Laser Cleaner

Product Description

Advantages of Laser Cleaning in the Semiconductor Industry

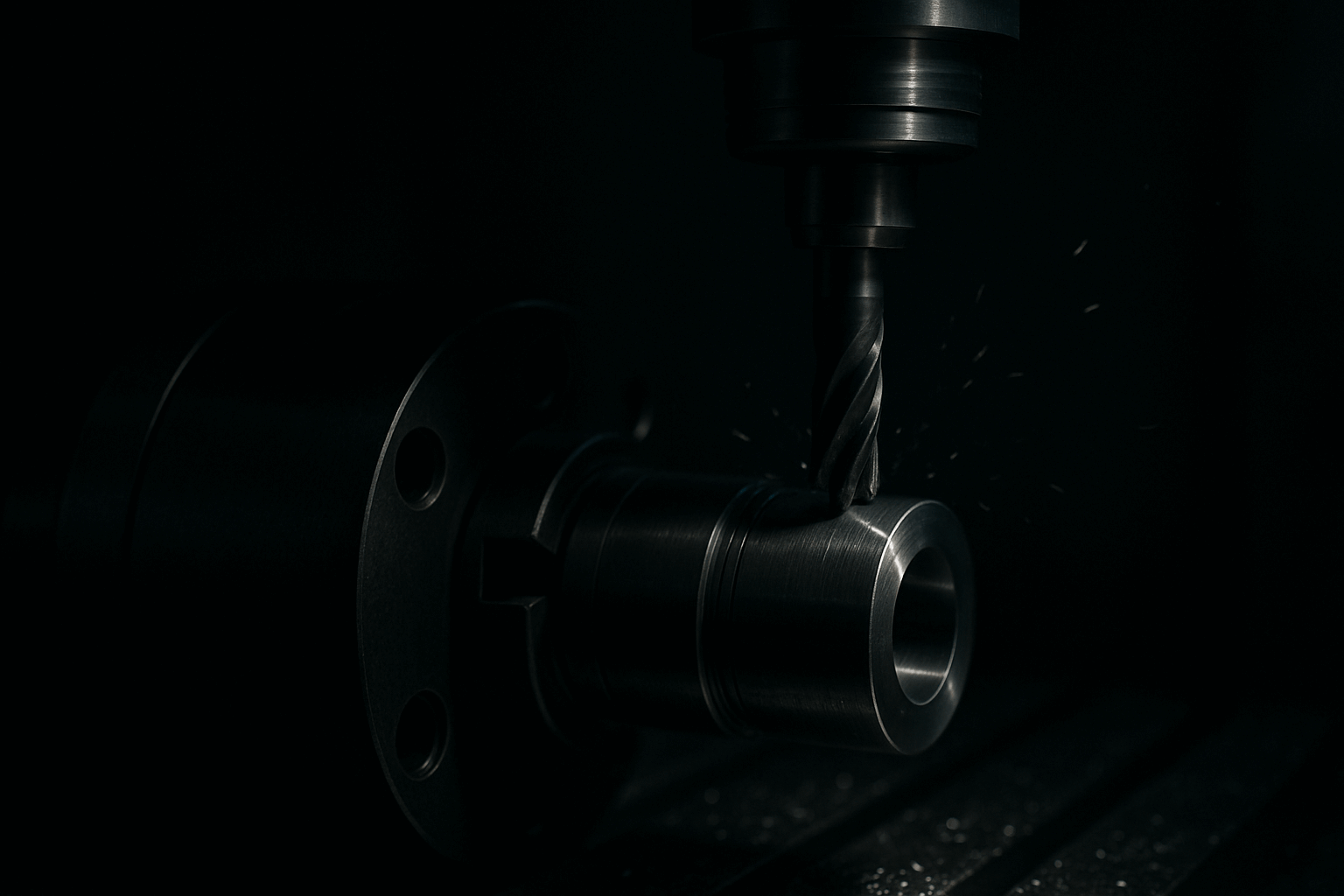

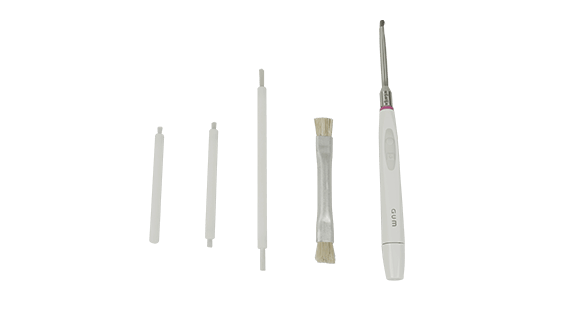

- High-Precision Cleaning: Removes tiny contaminants (tin dross, photoresist residues, etc.) without damaging the substrate

- Non-Contact & No Consumables: Suitable for compact devices like smartphones

- Improves Yield Rate: Ensures conductivity and product stability

- Removes Micro Contaminants: Eliminates nano-scale particles and organic residues.

- Eco-Friendly & Cost-Effective: No chemical solvents, reducing pollution and disposal costs.

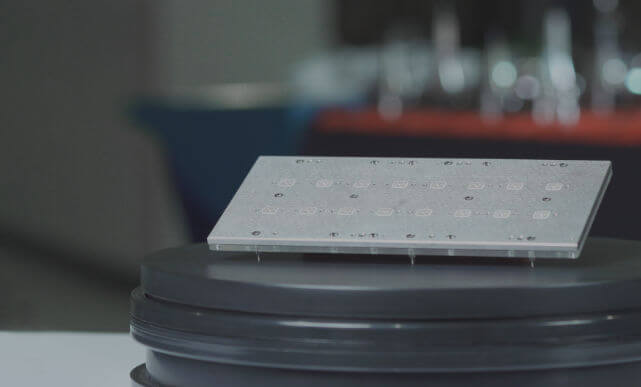

- Wide Application Range: Used for wafer, packaging, probe card, and PCB solder joint cleaning

- Precise Control: Adjustable laser parameters for optimal cleaning results Laser cleaning technology is widely used in semiconductor manufacturing due to its efficiency, precision, and eco-friendly nature, enhancing yield rate and process stability

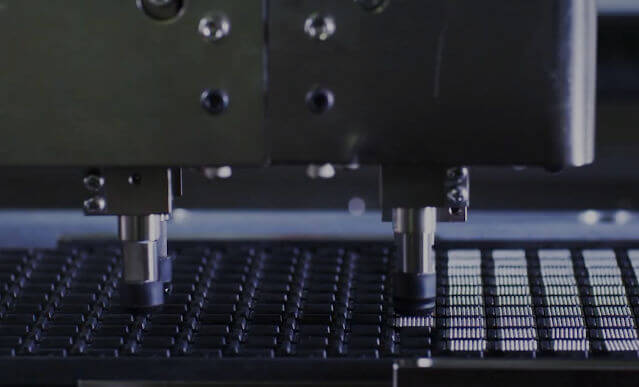

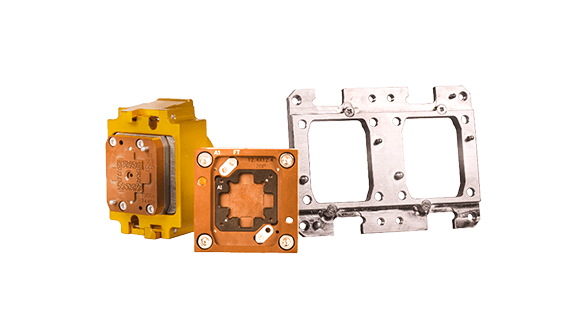

Laser Cleaner Use Cases in Semiconductor

-

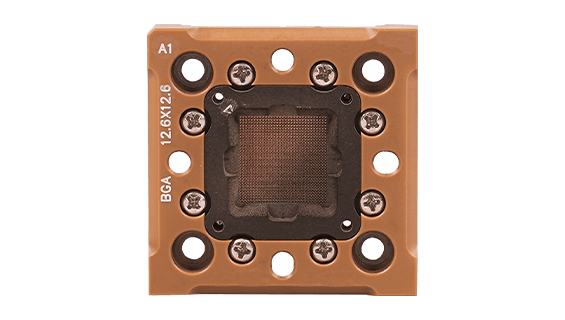

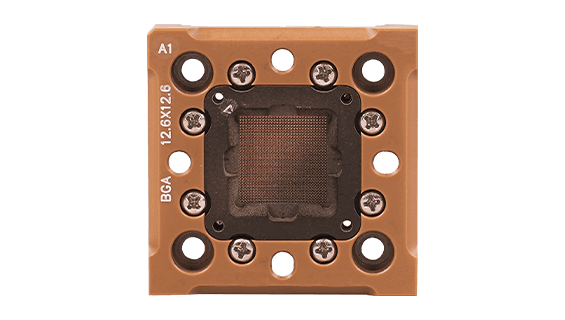

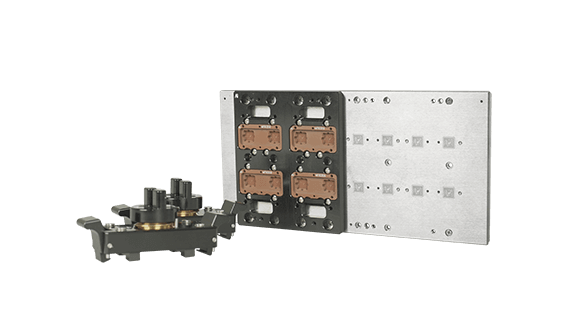

Pogo Pin Cleaning

Before After

-

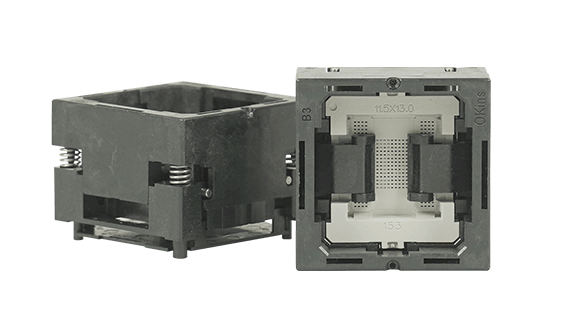

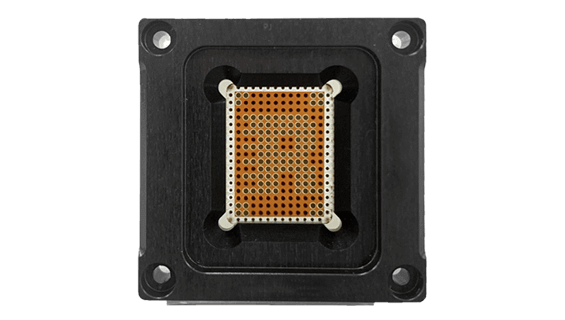

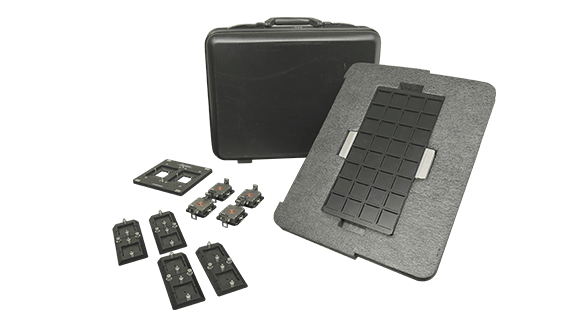

Finger Pin Cleaning

Before After

Product Specification

|

Max output power (1064nm)

|

When 1.5 Watts, corresponding to each energy is greater than 0.3 joules

|

|

Output power adjustment range (1064nm)

|

0.7 Watts to 1.5 Watts

|

|

Laser pulse width (1064nm)

|

below 50 ns (FWHM)

|

|

Operating temperature

|

between 15~40°C

|

MORE PRODUCTS

Contact Us Now

Complete online forms and Pin-Jet will have representatives to help you with professional services