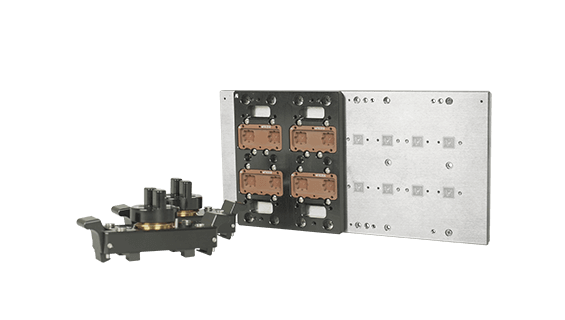

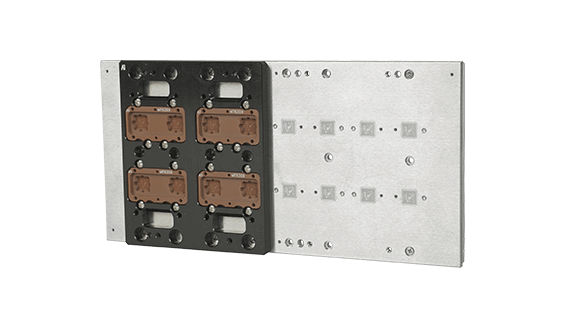

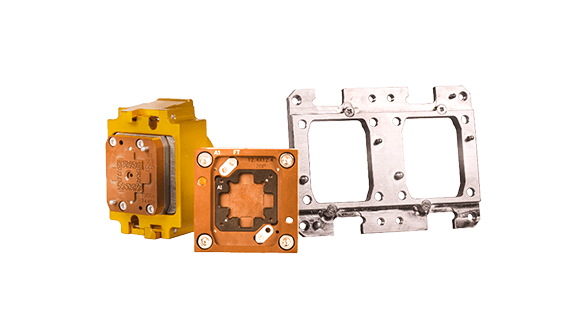

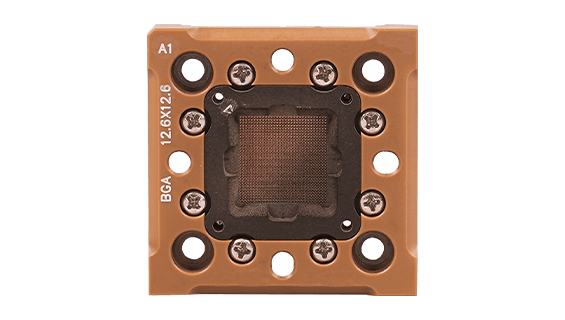

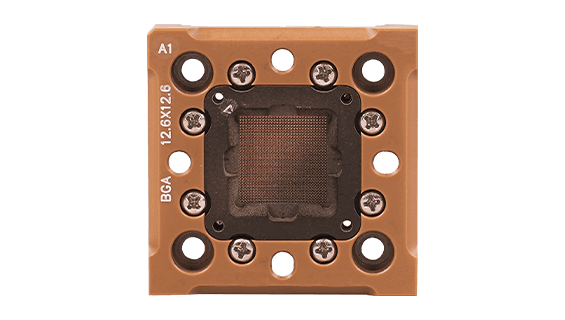

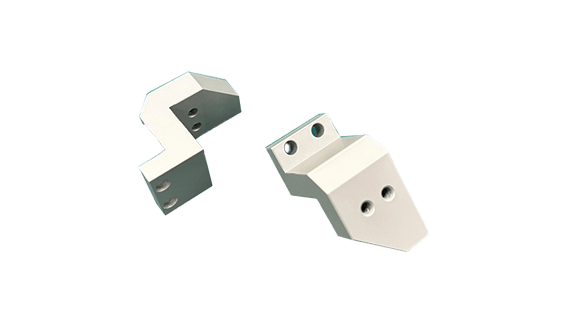

WLCSP Probe Heads

Product Description

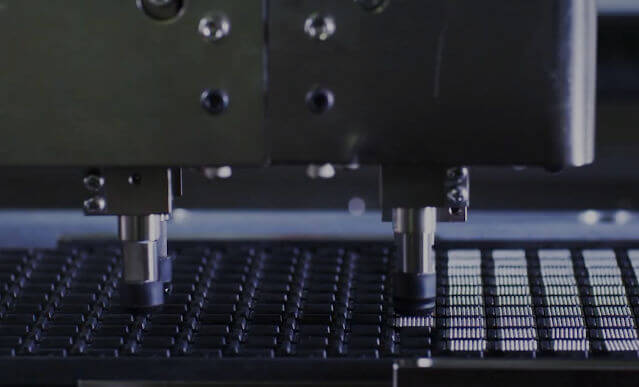

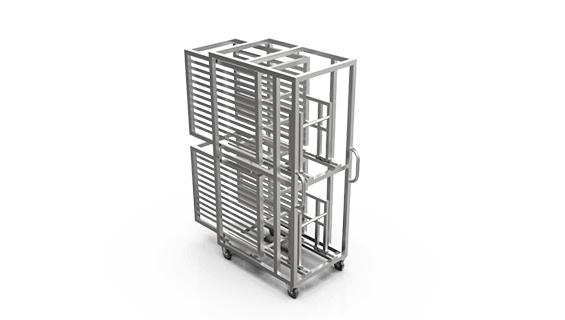

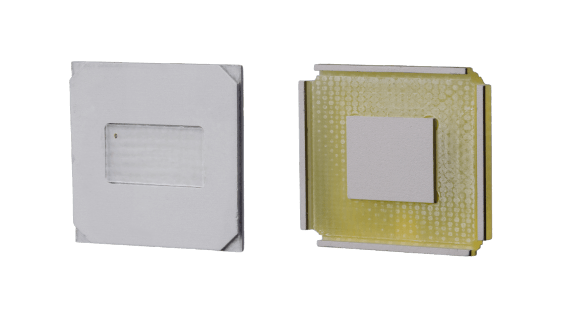

In Wafer Testing, the Probe Head is a critical testing component responsible for establishing an electrical connection between the testing equipment (e.g., Automatic Test Equipment, ATE) and each die on the wafer. This enables functionality and electrical performance testing. The design and performance of the Probe Head directly impact the accuracy, efficiency, and ultimately the yield rate of the testing process. Pin Jet is dedicated for wafer-level chip testing; probe heads can be manufactured with custom design for different number of sites according to customer's needs.

Key Features of the Pin-Jet Probe Head

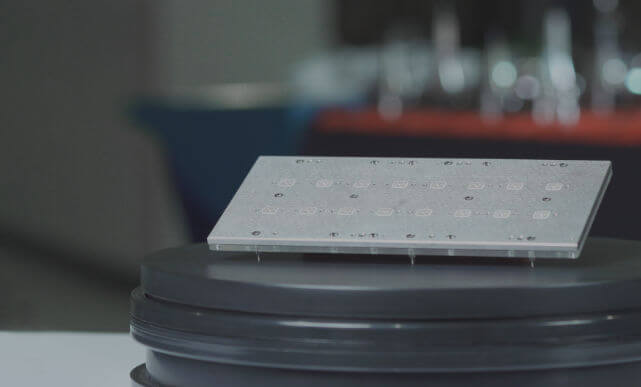

- Customized Design : Offers tailored socket designs specifically for WLCSP (Wafer Level Chip Scale Package) products, meeting customer requirements for multi-site testing.

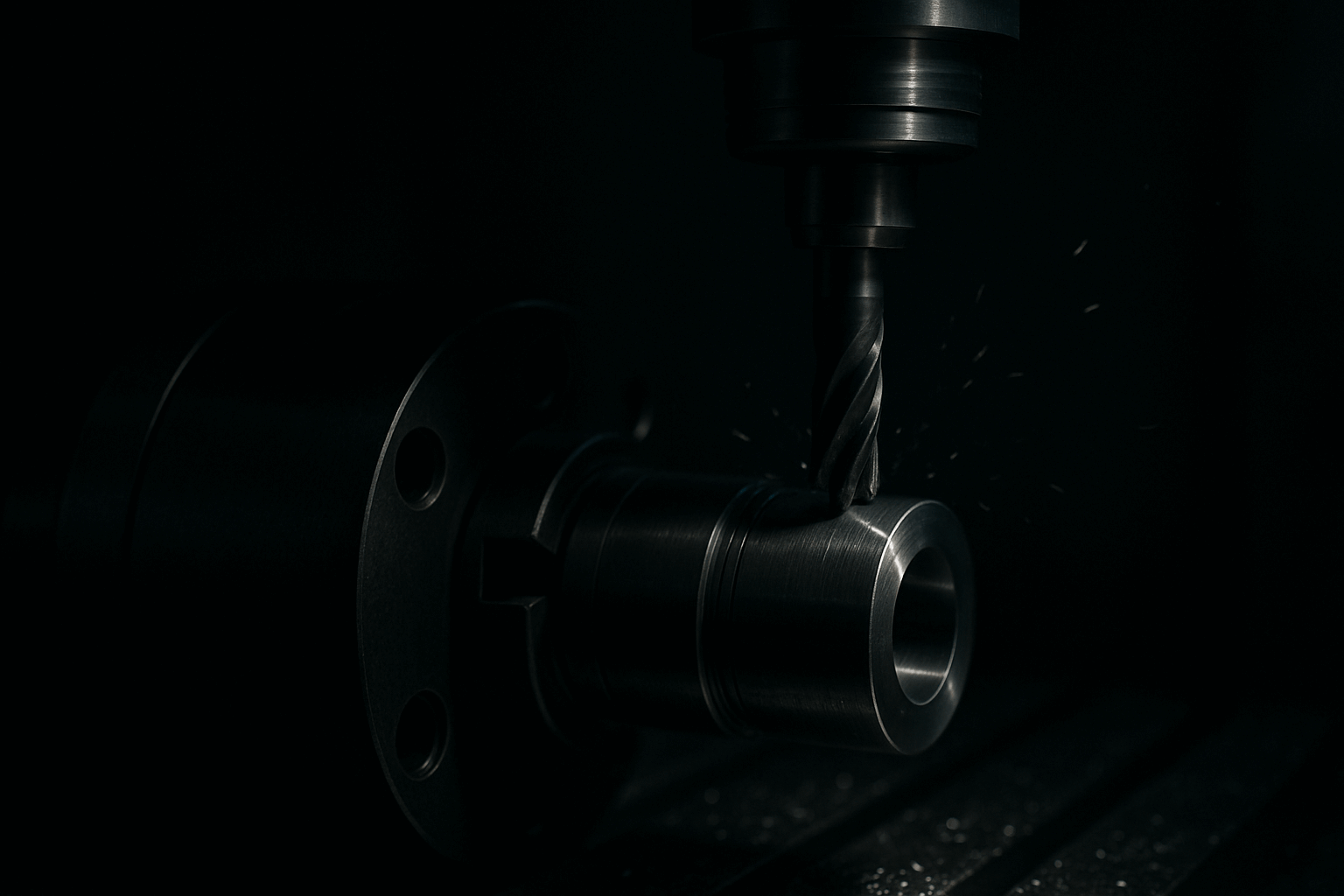

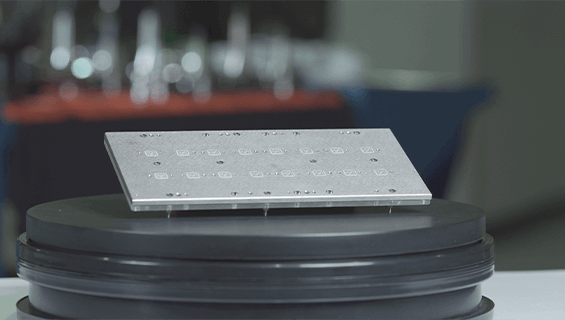

- High-Precision Manufacturing : Utilizes advanced manufacturing technologies to ensure the precision and durability of Probe Heads, suitable for testing high-frequency and high-performance computing products.

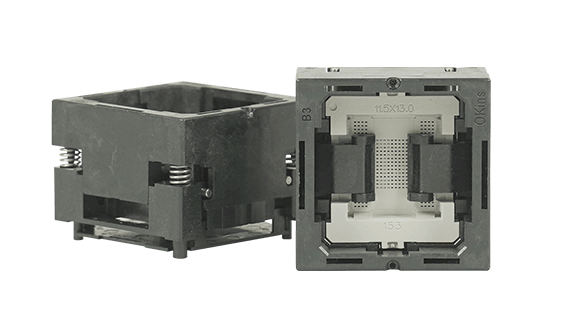

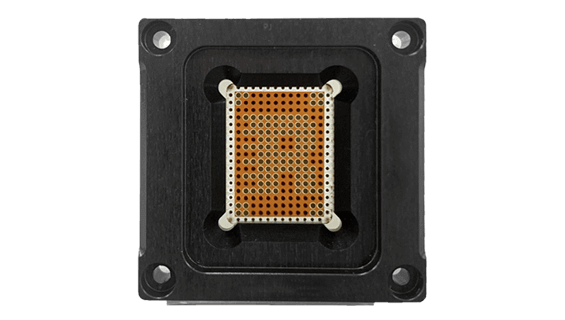

- Multi-Functional Applications : In addition to Probe Heads, Pin-Jet focuses on testing solutions for high-frequency and high-performance computing products, offering products such as PoP Sockets and Coaxial Sockets, striving to exceed customer standards.

- Professional Technical Support : Equipped with a specialized engineering team that develops cutting-edge products and technologies to meet the increasingly stringent demands of various industries.

FAQ About WLCSP Probe Head

1. What is the lifespan of the Probe Head?

"The lifespan of a Probe Head depends on testing conditions, probe material, and the number of contact cycles. Our Probe Heads are manufactured with highly durable materials, typically lasting for hundreds of thousands to millions of contact cycles. With proper maintenance, their lifespan can be effectively extended."

2. Does the Probe Head damage the wafer surface?

"Our Probe Head design incorporates elastic probes and precise pressure control technology, ensuring uniform and minimal contact pressure during testing. This significantly reduces the risk of damage to wafer test points. Additionally, the probe materials are optimized to minimize contact wear."

3. Does the Probe Head support high-frequency testing?

"Our Probe Heads are specifically designed to support high-frequency testing, making them suitable for applications in 5G communications, data centers, and high-speed transmission. Advanced materials and structural designs ensure signal integrity and testing accuracy."

4. Can the Probe Head perform parallel testing on multiple dies?

"Yes, our Probe Head is designed to support multi-die parallel testing, allowing it to contact multiple test points in a single operation, significantly improving testing efficiency. Additionally, we can customize the design based on your testing requirements to further optimize productivity."

5. Are the maintenance costs of the Probe Head high?

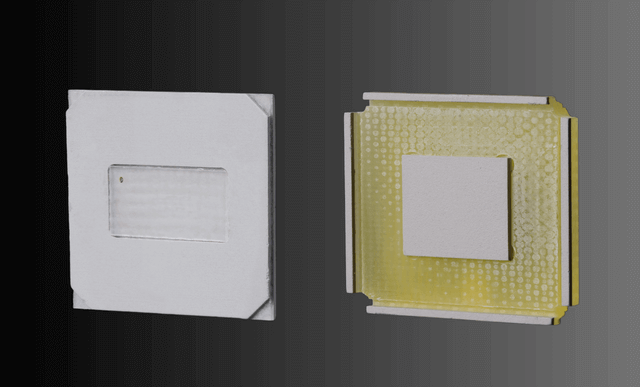

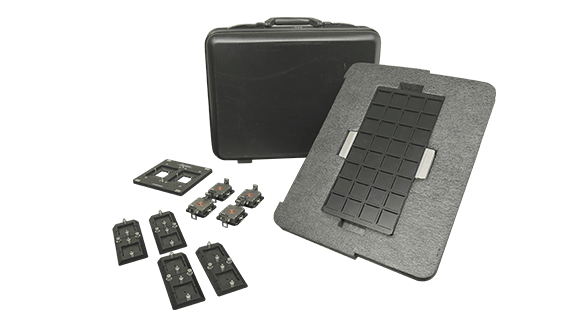

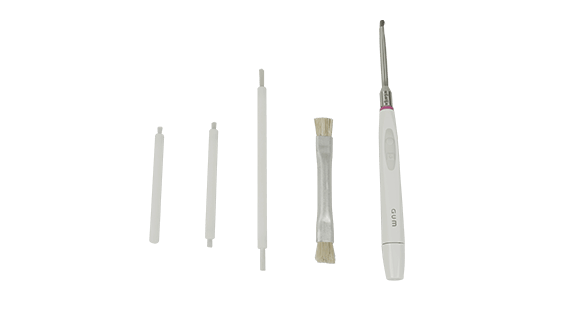

"Our Probe Heads are made from high-quality materials with strong durability, reducing the need for frequent maintenance. Regular cleaning and inspection can extend their lifespan and lower overall usage costs. We also provide specialized cleaning solutions, such as the Clean Pad, to ensure long-term stability and performance."

6. Can the Probe Head be customized?

"Absolutely! Our experienced engineering team can design a custom Probe Head based on your wafer specifications, testing conditions, and production requirements to ensure optimal testing performance and yield rates."

7. How do I determine if the Probe Head needs replacement?

"If issues such as poor contact, abnormal test data, or significant probe wear arise during testing, it may be time to replace the Probe Head. Regularly inspect the probe's shape and conductivity, and assess replacement needs based on contact cycles and test results. Our technical support team is available to provide professional advice."

8. Does the Probe Head support wafers of different sizes?

"Our Probe Heads are compatible with multiple wafer sizes. Additionally, we offer custom solutions for non-standard wafers to ensure both compatibility and testing accuracy."

9. How is signal integrity ensured?

"We use low-loss materials to design the probes and incorporate electromagnetic shielding technology in the structure. This effectively reduces signal reflection and interference, ensuring signal integrity. Our high-frequency testing solutions are specifically designed for high-speed applications."

10. What is the lead time for your Probe Head?

Product Specification

|

PKG

|

MODEL

|

SIZE

|

PIN COUNT

|

PITCH

|

|---|---|---|---|---|

|

WLCSP

|

Probe Head

|

~7x7

|

300

|

0.15mm

|

|

SPEC

|

|

|---|---|

|

Package

|

wlcsp

|

|

Pitch

|

>=0.25

|

|

Resistance

|

<=100mOhm

|

|

Bandwith

|

-1dB @40GHz

|

|

Temperature

|

-60~200

|

|

Current rating

|

0.5~4A

|

MORE PRODUCTS

Contact Us Now

Complete online forms and Pin-Jet will have representatives to help you with professional services