Clean pad

Product Description

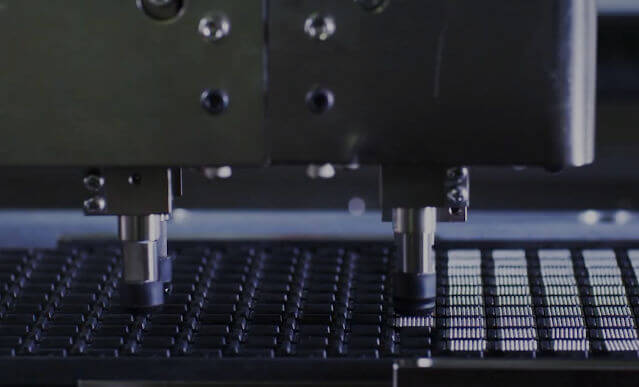

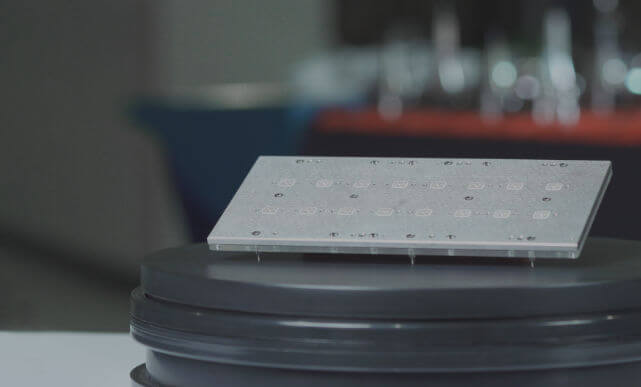

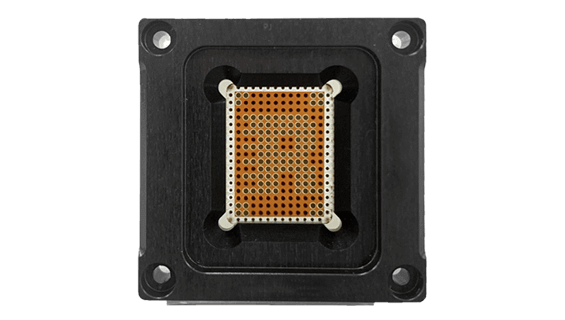

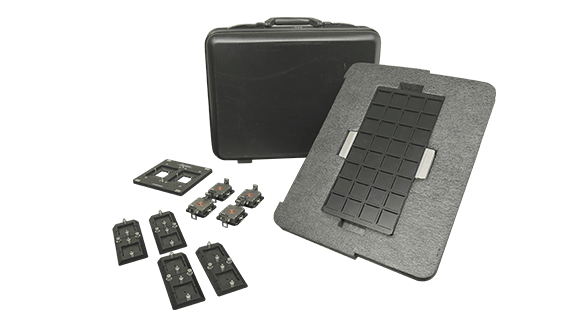

Our clean pad is developed by a professional team with complete in-house design and manufacturing capabilities, Clean Pad is custom-designed based on customer-provided socket drawings, IC drawings, and test conditions, ensuring tailored solutions that meet a wide range of application requirements.

Backed by extensive test data and customer validation, PJ’s Clean Pad delivers superior cleaning performance, with a lifespan of up to 1,500 touch-downs. It ensures no residue, causes no damage to probe tips, and offers high durability, effectively reducing downtime and significantly improving overall production efficiency.

To prevent moisture absorption and environmental degradation, Clean Pads are shipped in anti-static vacuum-sealed packaging to maintain optimal product condition.

After opening, it is recommended to store the product in a nitrogen cabinet or dry box to extend shelf life and ensure long-term performance stability.

Why Clean Pad

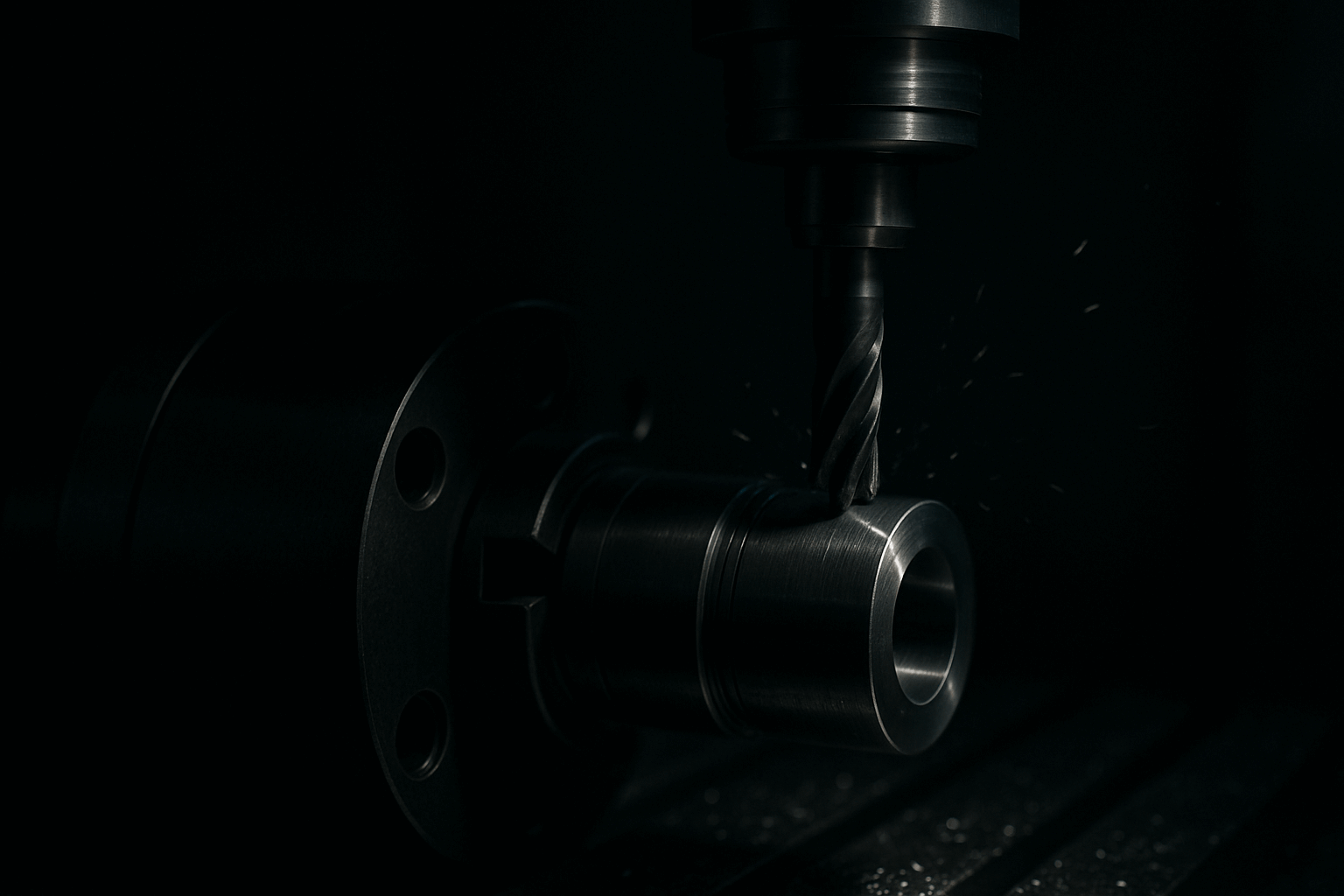

During IC testing, Pogo Pin tips are constantly exposed to varying temperatures, humidity levels, and electrical conditions. These harsh environments often lead to contamination—such as solder residue and carbon buildup—which increases contact resistance and can result in poor connections or test abnormalities.

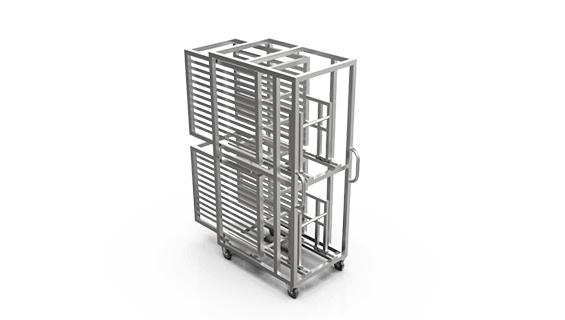

By using Clean Pad for automated cleaning, you can effectively replace manual cleaning methods and eliminate inconsistencies caused by operator handling. The result is efficient, stable, and consistent cleaning performance, significantly improving overall test quality.

✔ Reduces contact failure rate

✔ Extends socket lifespan

✔ Improves yield and test stability

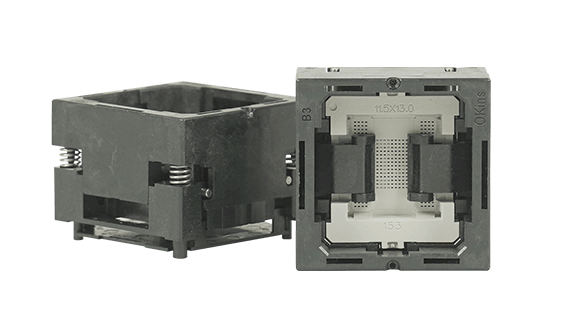

Clean Pad Compatibility with Various IC Package Types

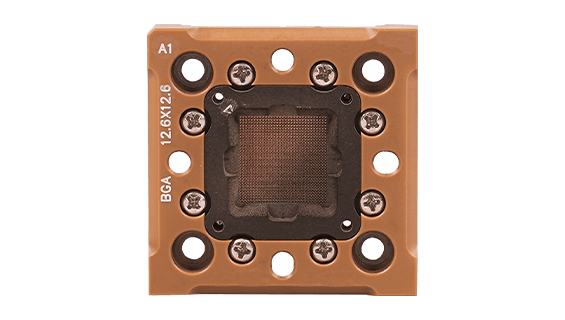

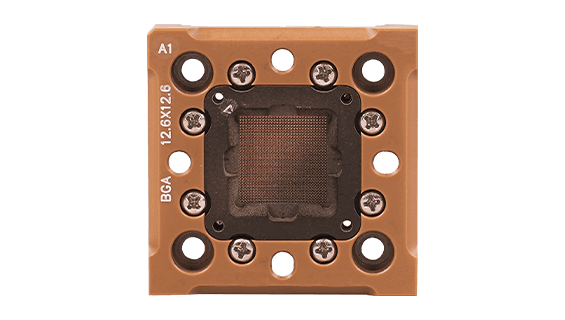

PJ offers customized Clean Pad designs to accommodate various IC package types, thicknesses, Pogo Pin sizes, and socket configurations.

Our solutions are tailored based on customer-provided IC packaging types, socket drawings, and kit drawings to ensure optimal cleaning performance and test reliability.

Currently supported package types include:

- QFN

- BGA

- (In development) QFP

This ensures broad compatibility and readiness for evolving market demands.

Clean sheet Datasheet(Si6000)

Si6000 Clean Sheet operates within a temperature range of 40°C to 200°C. It demonstrates exceptional high-temperature tolerance and consistent cleaning effectiveness, significantly improving cleaning results while reducing wear on pins and spring probes, thus prolonging the service life of testing equipment.

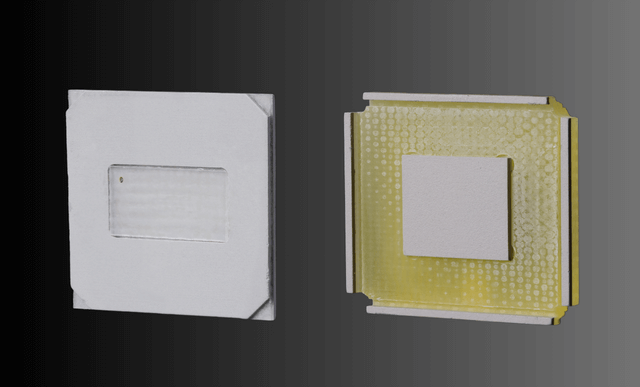

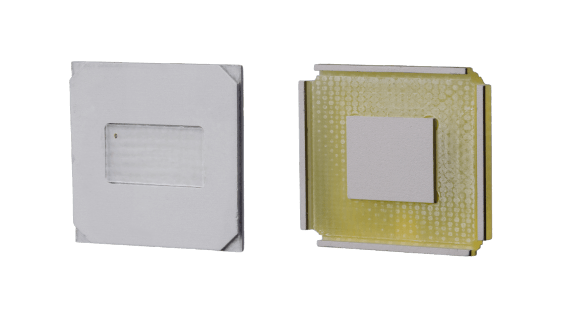

Temperature Verification

After 30 consecutive days of high-temperature testing at 125°C, the surface of the Si6000 Clean Sheet shows almost no visible change between the pre-test (left image) and post-test (right image), demonstrating outstanding heat resistance and stability. This makes it well-suited for high-temperature processes and long-term use environments.

Cleaning Effect

A performance comparison test was conducted over 25 days for products from two customers, evaluating results before and after cleaning with the Clean Pad:

-

Customer K – Product M:

The performance before cleaning (blue line) and after cleaning (red line) nearly overlap, indicating stable and consistent results post-cleaning and maintaining high operational standards. -

Customer S – Product M:

The green line represents the condition before cleaning, and the red line shows the results after using the Clean Pad. The data reveals a clear and steady improvement, with performance consistently maintained at a high level.

Clean sheet Datasheet(WA6000)

WA6000 Clean Sheet operates within a temperature range of -20°C to 140°C. It offers excellent heat resistance and stable cleaning performance, effectively enhancing cleaning efficiency while minimizing damage to pins, thereby extending the lifespan of testing equipment.

Temperature Verification

After undergoing continuous high-temperature testing at 110°C for 30 days, the surface of the WA6000 Clean Sheet shows almost no visible change between the pre-test (left image) and post-test (right image), demonstrating excellent heat resistance and stability.

Cleaning Effect

A 20-day performance test was conducted on Product A from Customer M and Customer S, comparing results before and after using the Clean Pad:

-

Customer M – Product A:

The blue line represents the condition before cleaning with the Clean Pad, while the orange line shows the results after cleaning. A clear and stable improvement in performance is observed post-cleaning. -

Customer S – Product A:

Likewise, the red line indicates the condition after using the Clean Pad. Compared to the pre-cleaning state shown by the blue line, the product maintains high performance across cycles, demonstrating the Clean Pad’s excellent and consistent cleaning effectiveness.

-

Customer M – Product A:

Clean Pad Case Study: Improved Test Yield and Quality Stability

A semiconductor packaging and testing company conducted a performance validation of Clean Pad at its Final Test (FT) station.

In the initial phase, across five consecutive lots, the First Yield ranged between 85% and 93%, showing significant fluctuations and relying heavily on multiple Retests (RT) to meet final standards.

After implementing Clean Pad and enabling the Auto Clean function, noticeable improvements were observed starting from just the first lot post-deployment:

- First Yield increased to 94.97%

- Subsequent lots stabilized between 96% and 98%

- Final Yield consistently stayed above 98.5%

- RT counts decreased, reducing test time and rework

Clean Pad Integration Results:

- Reduced Pogo Pin contamination, avoiding contact failures

- First Yield improved by 5%–10%, with enhanced test stability

- Fewer retests required (RT stabilized at 2 times per lot)

- Recommended cleaning frequency: once per hour, with 5–10 cleaning strokes per cycle

Clean Pad Frequently Asked Questions (FAQ)

Q: What is the size range available for Clean Pad production?

Pin-Jet can customize Clean Pad designs based on the dimensions of your IC and socket. The smallest Clean Pad size currently available is 1.5 mm.

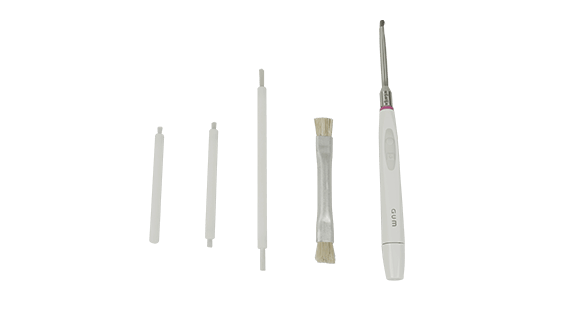

Q: What materials are used for the Clean Pad?

- Clean Sheet: Pin-Jet uses an adhesive-style design that leverages the test contact mechanism to penetrate and reach the inner SiC layer for effective cleaning. It supports a wide temperature range from –40 °C to 200 °C, suitable for various testing environments.

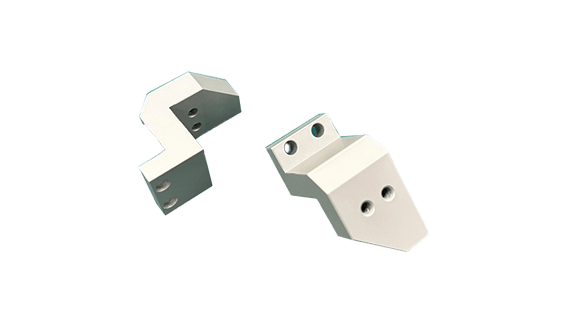

- Clean Pad Substrate: Made of FR4 material, offering superior hardness, pressure resistance, and heat resistance. Its flatness also surpasses other market alternatives, ensuring stable testing performance and extended product lifespan.

Q: What is the lifespan of the Clean Pad?

The lifespan of the Clean Pad varies depending on the actual testing environment. Based on customer feedback, it can withstand approximately 1,500 touch-down cycles while maintaining excellent cleaning performance and stability.

Q: Will different types or materials of pins require different Clean Pad designs?

Yes. The design of the Clean Pad is adjusted according to the type of pin to ensure optimal cleaning performance while maintaining testing yield and product lifespan.

Q: What information is required to design a Clean Pad?

Since Pin-Jet Clean Pads are customized, providing the following drawing information will help us deliver the optimal solution more quickly and accurately:

- IC Drawing

- Socket Drawing

- Kit Drawing

- Test Temperature

Q: What types of packages are compatible with the Clean Pad?

Pin-Jet can assist customers in customizing Clean Pads for various package types, such as QFN, BGA, and QFP, among others.

Product Specification

|

Clean sheet Datasheet(WA6000) Surface SEM photo |

Clean sheet Datasheet(Si6000) Surface SEM photo |

||

|

|

|

||

| Surface SEM photo | Cross-section SEM photo | Surface SEM photo | Cross-section SEM photo |

|

|

|

|

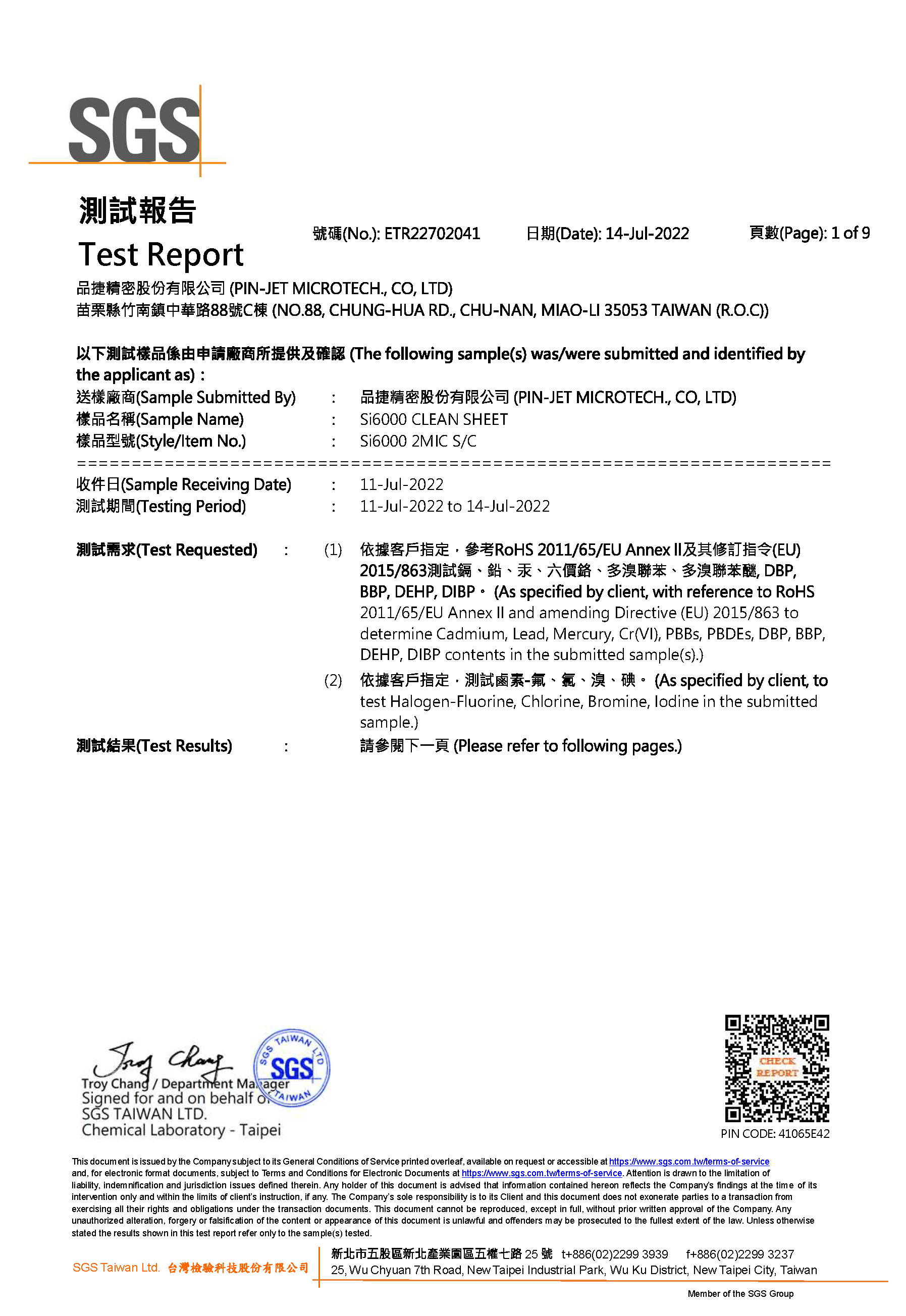

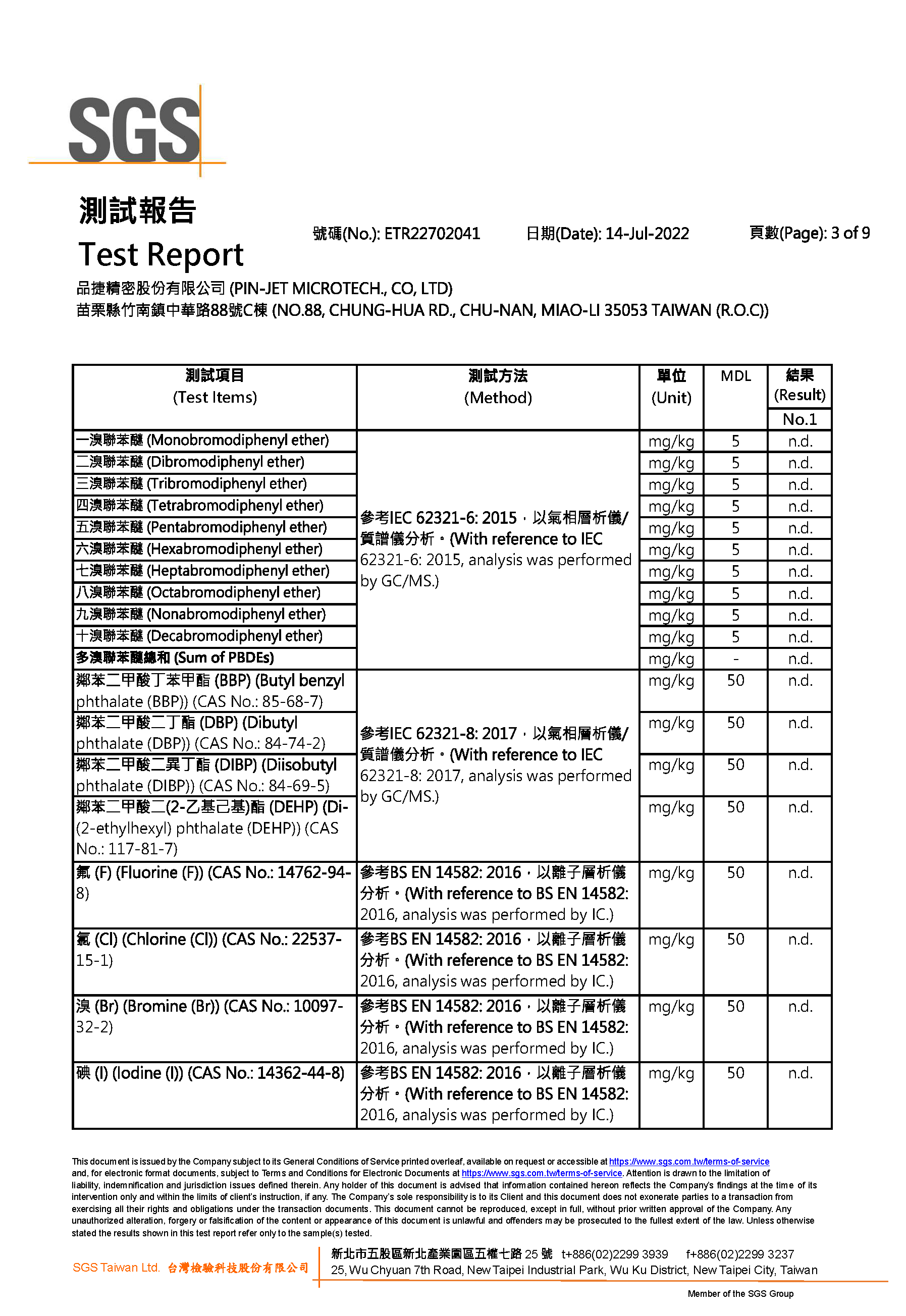

Si6000 Halogen Content Four-Item Test Report

Si6000 Volatile Siloxane Analysis Report

WA6000 SGS Inspection Report

Back Cover Substrate Material (G11)

|

JIS Grade

|

EL-GEH

|

|

NEMA Grade

|

G11

|

|

UL-94 Frame

|

94V-0

|

|

MIL-P Grade

|

18177C -GEE

|

|

RESIN & BAS

|

Epoxy Glass Cloth

|

|

Through-thickness 1-minute dielectric strength (kV/mm)

|

15 ~ 20

|

|

Through-thickness breakdown voltage (kV/mm)

|

25 ~ 35

|

|

Surface 1-minute dielectric strength (kV/mm)

|

25

|

|

Surface breakdown voltage (kV/mm)

|

45 ~ 60

|

|

Volume resistivity (Ω·cm)

|

5 x 10 13

|

|

Surface resistivity (Ω)

|

5 x 10 14

|

|

Tensile strength (kg/mm²)

|

30 ~ 32

|

|

Flexural strength (kg/mm²)

|

35 ~ 45

|

|

Compressive strength (kg/mm²)

|

35 ~ 45

|

|

Impact strength (kg·cm/cm²)

|

70 ~ 80

|

|

Specific gravity

|

1.9 ~ 2.1

|

|

Hardness (HR-R)

|

130 ~ 135

|

|

Color

|

Light Yellow

|

|

Water absorption (%)

|

0.14

|

|

Heat resistance (°C / 2 hr)

|

200 ~ 210

|

|

Flame resistance

|

NON-BURNING

|

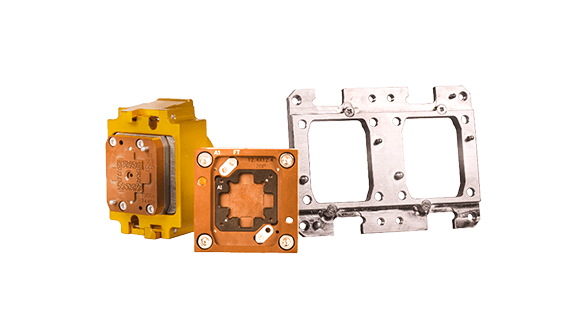

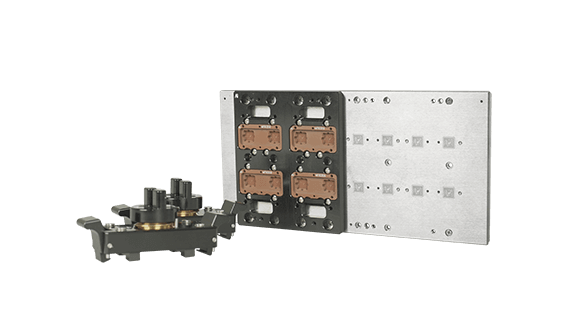

Customized Design

|

Type

|

Front

|

Side

|

Back

|

Product design

|

|---|---|---|---|---|

|

Single Side For QFN/BGA Package |

|

|

|

Suitable for networking servers and general‑purpose ICs. Uses an optimized‑stroke Contact Socket PIN Clean design that avoids PCB passive components and heat sinks. |

|

|

|

||

|

|

|

||

|

Double Side For PoP Package |

|

|

|

Dual‑sided cleaning layers clean both upper and lower socket pins during actuation, and the layout can accommodate the Handler KIT pick‑up position. |

|

QFP/LQFP Package |

|

|

|

The cleaning layer is designed to match the contact geometry between IC leads and socket pins; the actuation mechanism enhances the Clean unit effectiveness on the leads. |

MORE PRODUCTS

Contact Us Now

Complete online forms and Pin-Jet will have representatives to help you with professional services