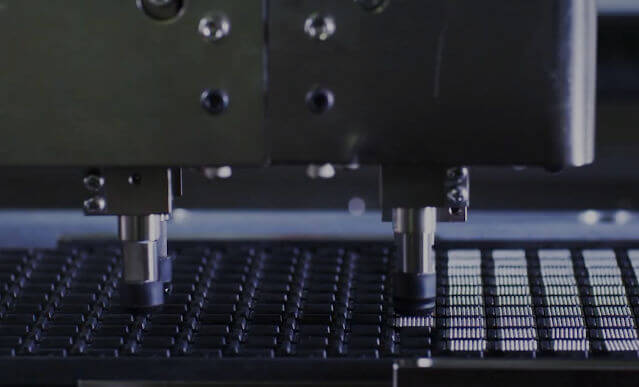

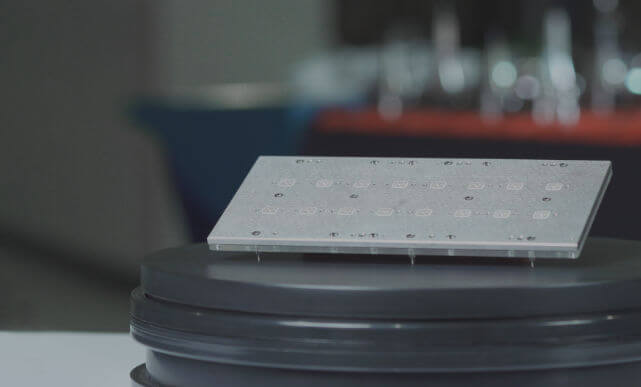

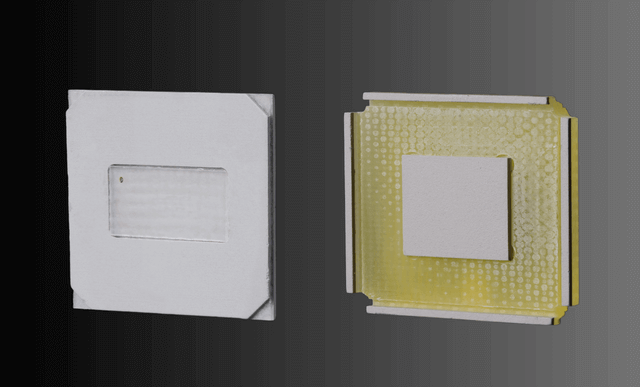

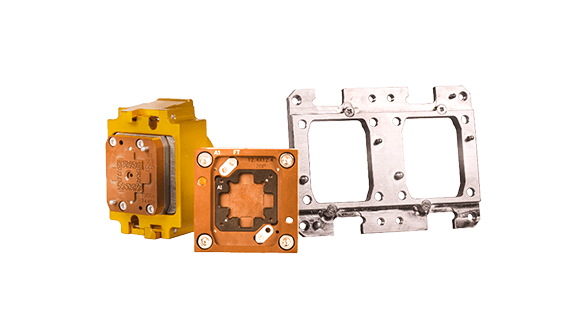

Automated Testing Sorter Components

Machine Specifications Overview

|

Machine Model

|

【1】LIMAC Sigma8+

|

【2】LIMAC Sigma9+

|

|---|---|---|

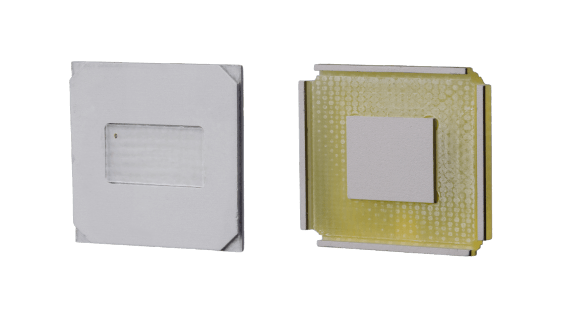

|

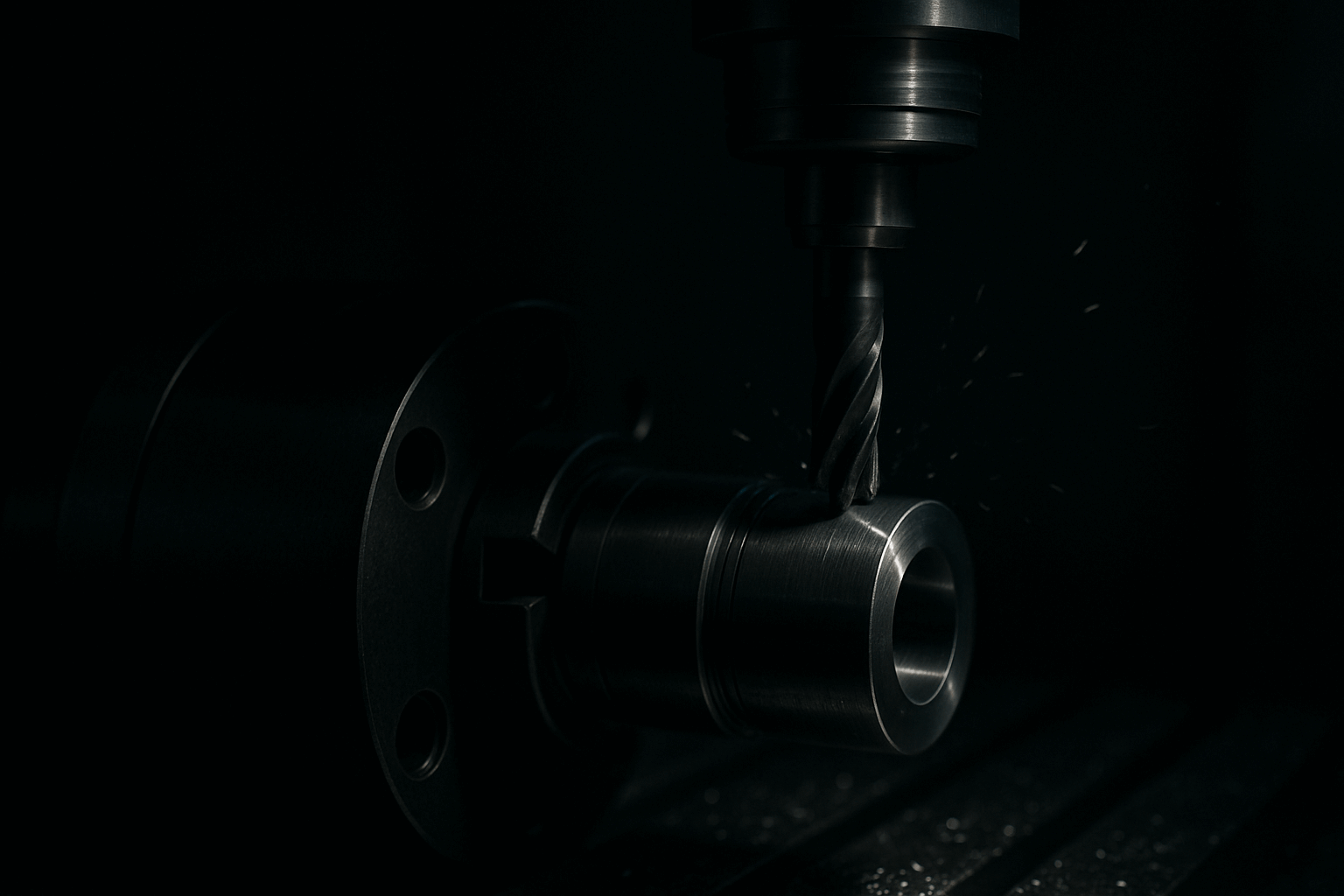

Photo

|

|

|

|

Machine Type

|

Vertical High-Speed Machining Center

|

Vertical High-Speed Machining Center

|

|

X/Y/Z Travel

|

850 / 550 / 600 mm

|

1000 / 600 / 600 mm

|

|

Spindle Speed

|

12,000 rpm

|

10,000 rpm

|

|

Number of Axes

|

3-axis

|

4-axis

|

|

Controller

|

FANUC 0i-Md

|

FANUC 0i-Md

|

|

Features

|

Tool length measurement;

High-precision machining of complex parts |

Tool length measurement;

Efficient automation for small to medium parts |

|

Machine Model

|

【3】CHAM-MILL CMV-6H

|

【4】CHAM-MILL CMV-8H

|

|---|---|---|

|

Photo

|

|

|

|

Machine Type

|

Vertical Machining Center

|

Large Vertical Machining Center

|

|

X/Y/Z Travel

|

600 / 400 / 400 mm

|

800 / 500 / 500 mm

|

|

Spindle Speed

|

15,000 rpm

|

15,000 rpm

|

|

Number of Axes

|

3-axis

|

4-axis

|

|

Controller

|

FANUC 0i-TF plus

|

FANUC 0i-TF plus

|

|

Features

|

Precision machining for molds and aluminum parts;

Tool length measurement, XYZ optical scales |

Suitable for large workpieces and heavy-duty cutting;

Tool length measurement, XYZ optical scales |

MORE PRODUCTS

Contact Us Now

Complete online forms and Pin-Jet will have representatives to help you with professional services