You can find the answer of our products and services.

Or you can contact us anytime.

According to the problem you encounter, what solutions can we provide for you?

1. Provide solutions for abnormal test yields.

2. Provide the best cleaning solution for tin staining on pins.

3. Provide the competitive price.

4. Provide the most appropriate solutions to optimize production line improvements.

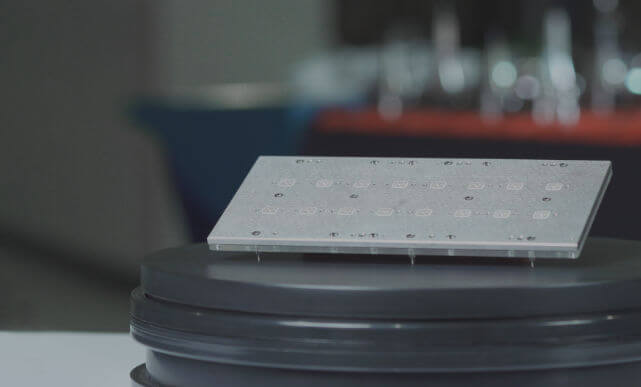

Manufactured chips are accepted and checked to see whether the chips can operate normally. They are tested before packaging to ensure the reliability and yield of each wafer, and eliminate defective chips so that only the good chips will be packaged. Of course, they still need to be tested after they are packaged to make sure no problems occurred during the packaging process.

Any industry that needs to perform functional tests and electrical tests needs it. Such as: automobile, semiconductors, LED, solar power, LCD and biomedicine, etc., all need testing fixtures.

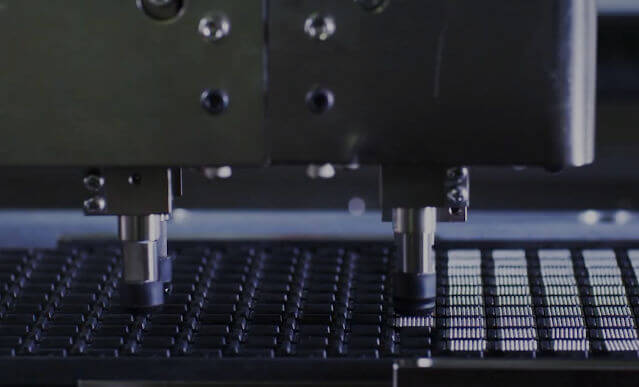

Pogo pin is a type of connector used for electrical transmission and connection; different specifications can be selected according to actual job requirements.

Simply provide the IC POD, test environment, and the related electrical and IC application range, and we can choose the pin most suitable for you.

Each IC has corresponding electrical tests; thicker pins are not always better.

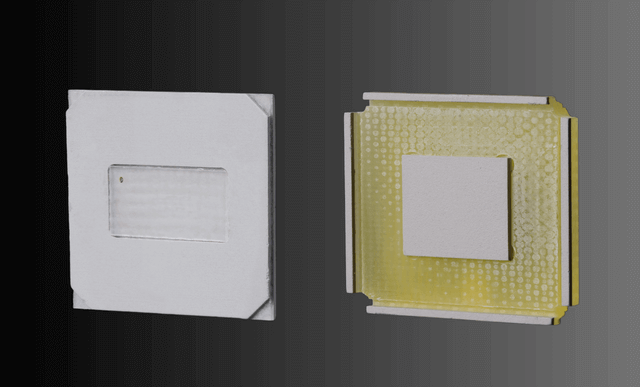

It's made by hot press stacking multiple layers of “conductive silicone” and “insulating silicone”. Since conductive adhesives aren't like pogo pins and don't need to be inserted into any test objects, the integrity of the test object can be retained; it's mainly used for IC BGA packaged products.

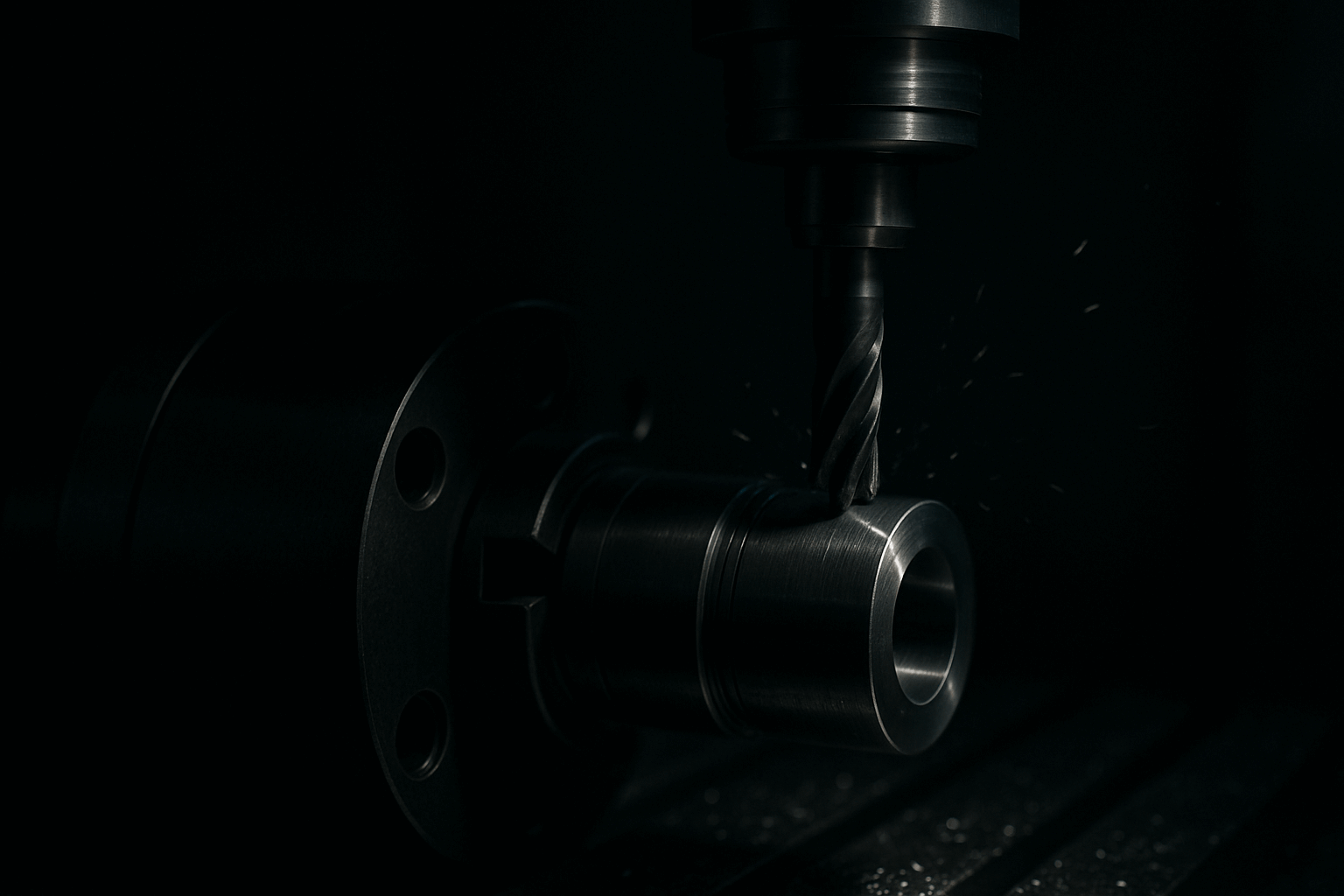

The cleaning methods mainly include online clean & offline clean; it's recommended to use a clean pad for online clean. For offline clean, we suggest you to use a brush and laser machine. Pin-Jet can provide the most suitable solution according to the actual application scenario of the customer.

Laser cleaning has the benefit of non-contact. Through the high temperature of laser, particles are vaporized instantly, achieving the effects of quick elimination and low environmental contamination.

Currently, the most common cleaning solution used in the IC testing industry is online clean; Clean pad can clean the pogo pin at set times consistently. Its feature is maintaining a good test yield, and it can avoid reduced cleaning effects due to the different cleaning methods of personnel.

One of the factors for poor cleaning effects is different clean methods. And everyone also has different strength, and cleaning too hard will damage the tip of the pin, resulting in reduced life time.

Contact Us Now

Complete online forms and Pin-Jet will have representatives to help you with professional services