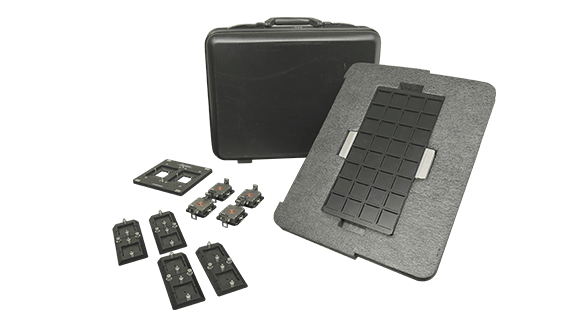

Burn in Socket

Product Description

The overview of burn-in socket?

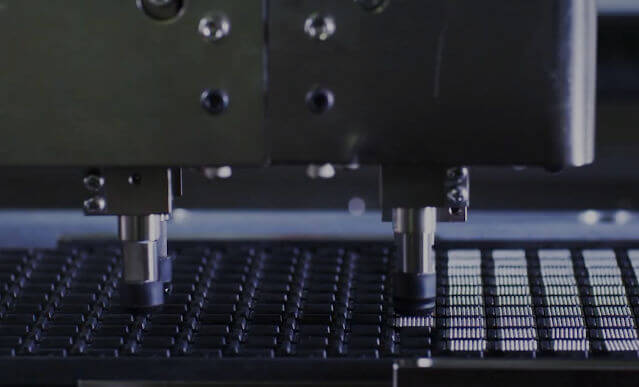

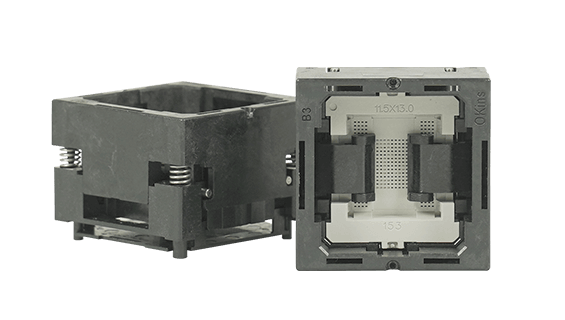

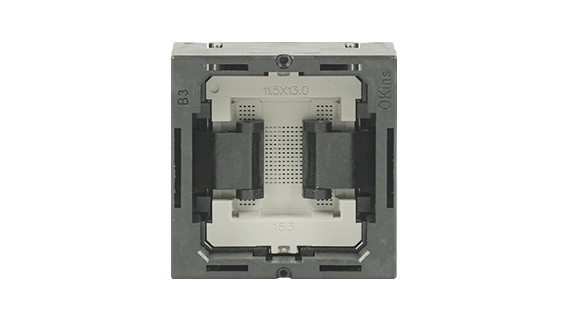

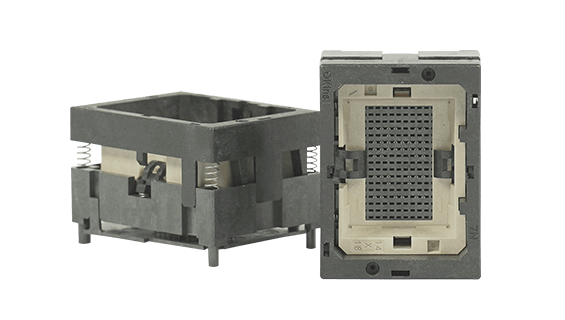

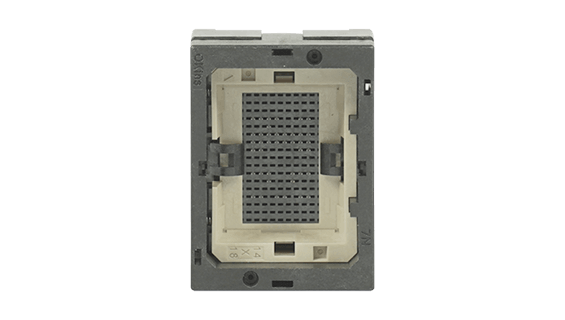

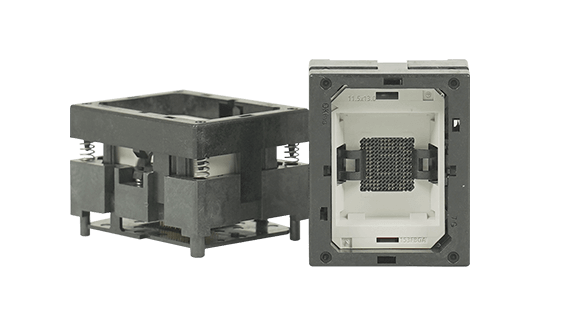

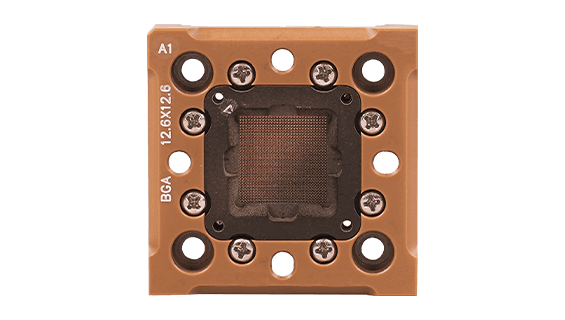

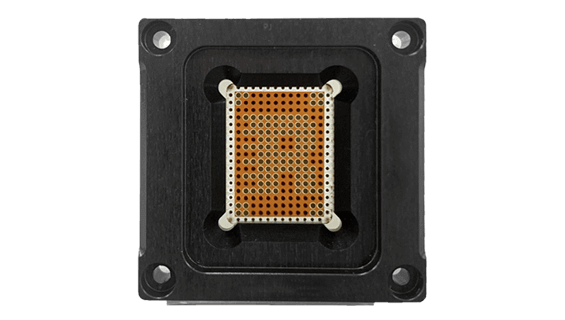

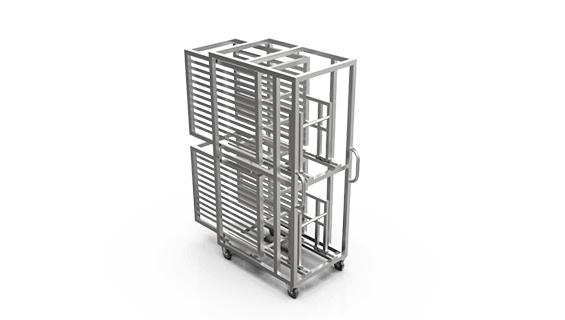

Burn-in socket is a tool used in semiconductor testing, designed to conduct prolonged stress tests on components under high and low temperatures. This process helps identify early failures and enhance product reliability. The socket is built to withstand extreme temperatures, offers durability, and provides precise connections to various component packages, ensuring stable electrical connectivity. It is widely used in semiconductor manufacturing and testing.

Burn-in test socket manufacturers

Pin-Jet excels in high-precision manufacturing, robust durability, customized design solutions, professional technical support, and extensive industry expertise. These strengths ensure the stability, reliability, and adaptability of their products. As a result, PinJet's Burn-in sockets are a superior and dependable choice, particularly for customers demanding precise and durable testing equipment.

|

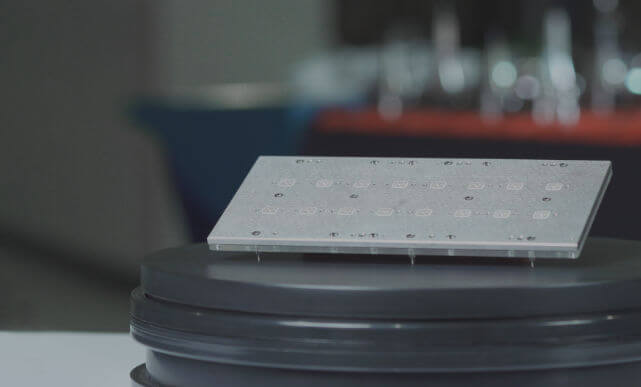

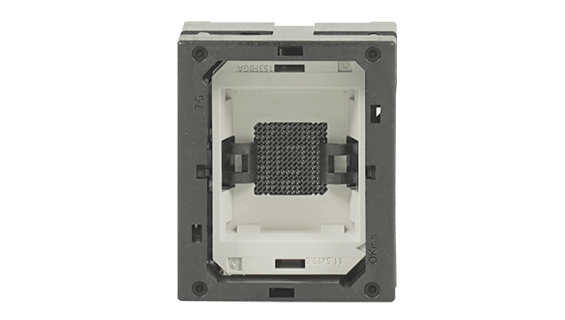

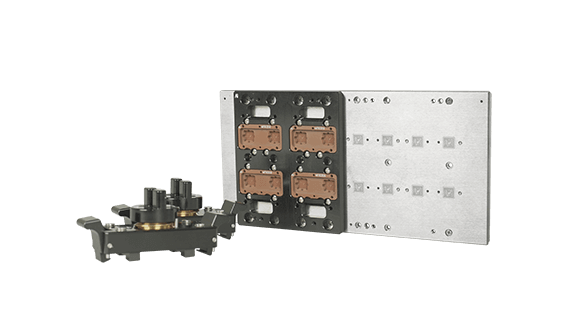

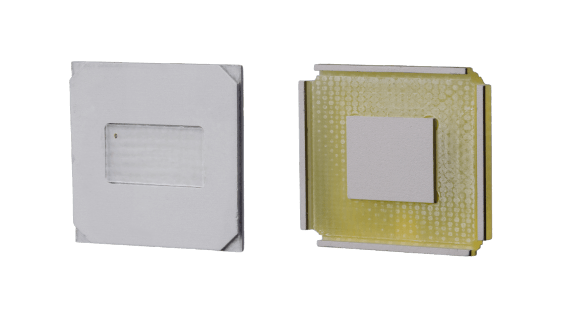

DIP Type (Soldering)

|

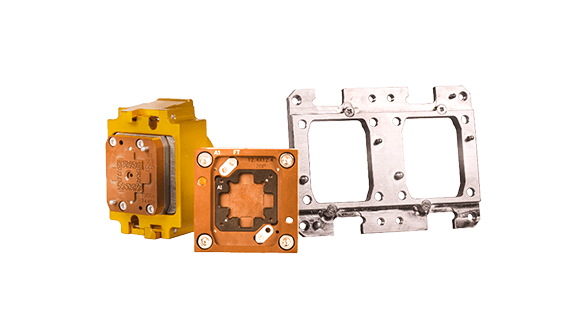

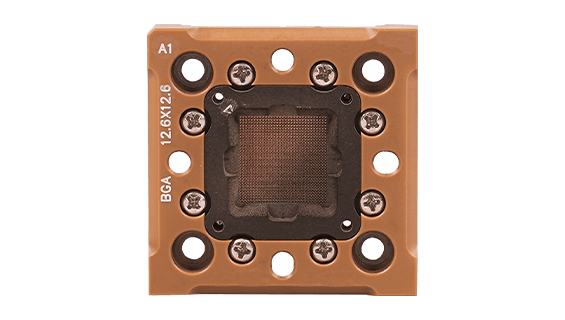

SMT Type (Screw Fixation)

|

|---|---|

|

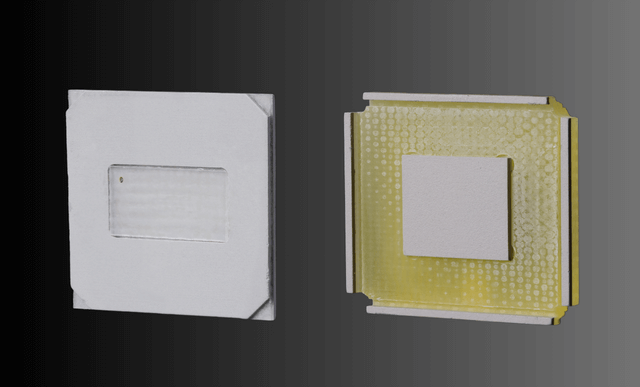

1.Pinch Contact

2.Dual Contact 3.Buckle beam Contact |

1.Buckle beam Contact

|

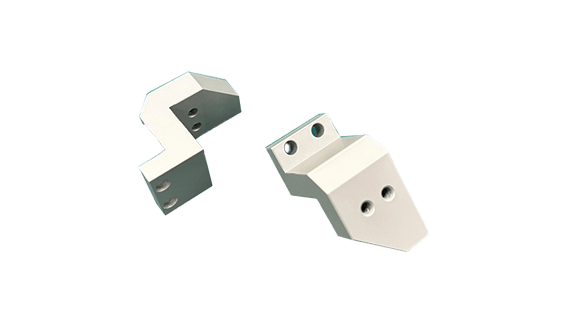

Product Specification

Provide Socket types:

- Memory testing:DDR、DDR-II、DDR-III、SDRAM、GDDR、SRAM、GDD

- Embedded memory testing:EMCP、EMMC、UFD、Micro SD、SD

- Assy type:BGA、CSP、TSOP、QFP、CLCC、QFN、LGA

MORE PRODUCTS

Contact Us Now

Complete online forms and Pin-Jet will have representatives to help you with professional services