IC test sockets are pivotal in semiconductor manufacturing, acting as the crucial interface between ICs and testing equipment. These sockets ensure that ICs conform to performance and quality standards before integration into larger systems. Their adaptability to various IC package types, including BGA and QFN, is essential for their broad applicability across different applications. By providing stable and reliable connections during the testing process, IC test sockets facilitate the detection of defects, ensuring that only high-quality chips advance to the next production stage.

We provide high-quality IC test sockets specifically optimized for final testing in semiconductor manufacturing. Our offerings include PoP, BGA/QFN, standard, and surface-mount matrix sockets, all engineered for precision and durability in high-volume production. These sockets feature advanced thermal management and flexible design capabilities, ensuring that your ICs meet the most rigorous quality standards. PinJet’s solutions offer the reliability and accuracy necessary to ensure flawless performance before your product reaches the market.

-

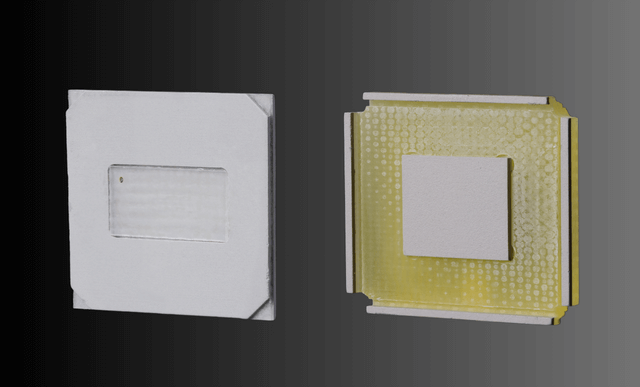

Package on Package Socket

Package on Package Socket

A Reference IC is required for comparison or memory operation during testing, and designed on the contact jig to shorten the electrical distance to get better effect on electricity.

Package on Package Socket

A Reference IC is required for comparison or memory operation during testing, and designed on the contact jig to shorten the electrical distance to get better effect on electricity.

-

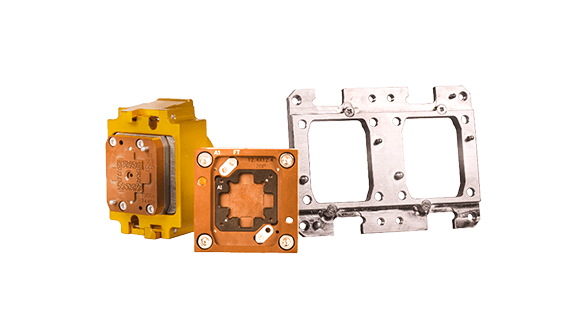

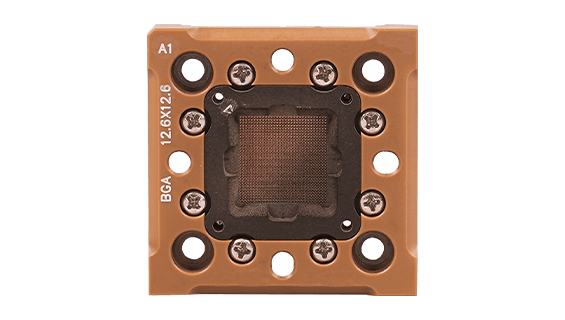

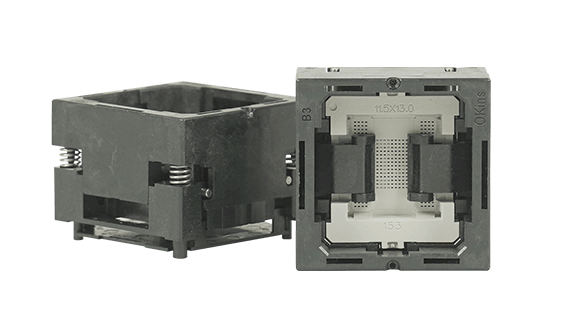

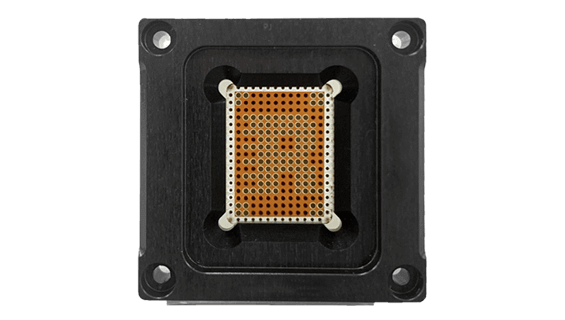

BGA Final Test Socket

BGA Final Test Socket

This is a commonly used type in the industry and can be applied to BGA/QFN/QFP...etc. In addition to pogo pin type socket, there are also finger pin type sockets.

BGA Final Test Socket

This is a commonly used type in the industry and can be applied to BGA/QFN/QFP...etc. In addition to pogo pin type socket, there are also finger pin type sockets.

-

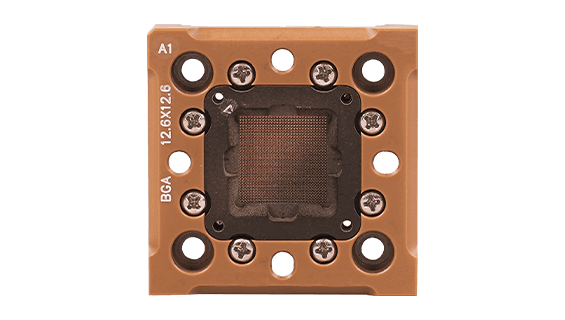

QFN Final Test Socket

QFN Final Test Socket

This is a commonly used type in the industry and can be applied to BGA/QFN/QFP...etc. In addition to pogo pin type socket, there are also finger pin type sockets.

QFN Final Test Socket

This is a commonly used type in the industry and can be applied to BGA/QFN/QFP...etc. In addition to pogo pin type socket, there are also finger pin type sockets.

-

Burn in Socket

Burn in Socket

Burn-in test socket is mainly used in the performance testing, environmental testing and life testing for commercial products, industrial products, military goods, and so on.

Burn in Socket

Burn-in test socket is mainly used in the performance testing, environmental testing and life testing for commercial products, industrial products, military goods, and so on.

-

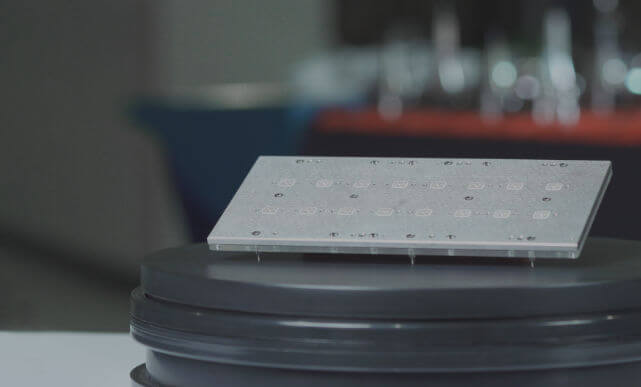

PCR Test Socket

PCR Test Socket

The conductive adhesive Socket has excellent electricity and is suitable for high-frequency, high-speed and other chip tests to ensure that the solder balls will not leave indentations.

PCR Test Socket

The conductive adhesive Socket has excellent electricity and is suitable for high-frequency, high-speed and other chip tests to ensure that the solder balls will not leave indentations.

-

Wafer Test

PROBE HEAD Wafer TestCustomize sockets for WLCSP products to meet customers’ needs for multiple-site testing

More -

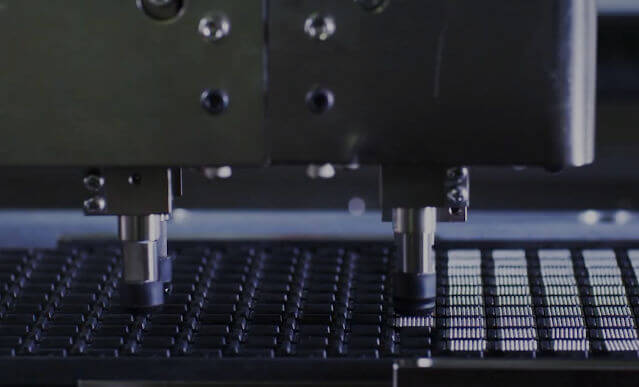

Change Kit

KIT Change KitProvide Pick & Place and SLT sorting machine jigs ranging from single site to 16 sites. The standard surface treatment we offer is hard anodizing. Anti-ESD surface treatment or special designs are also available at customer's request.

More -

Clean Tool

CLEAN TOOL Clean ToolThe Test Socket is a critical interface component in the semiconductor testing process, used to connect testing equipment with the device under test (such as BGA or QFN), enabling accurate functionality and performance testing.

More

As testing frequency and density increase, maintaining the cleanliness of the Test Socket becomes crucial for ensuring the accuracy of test results, extending equipment lifespan, and improving production efficiency. -

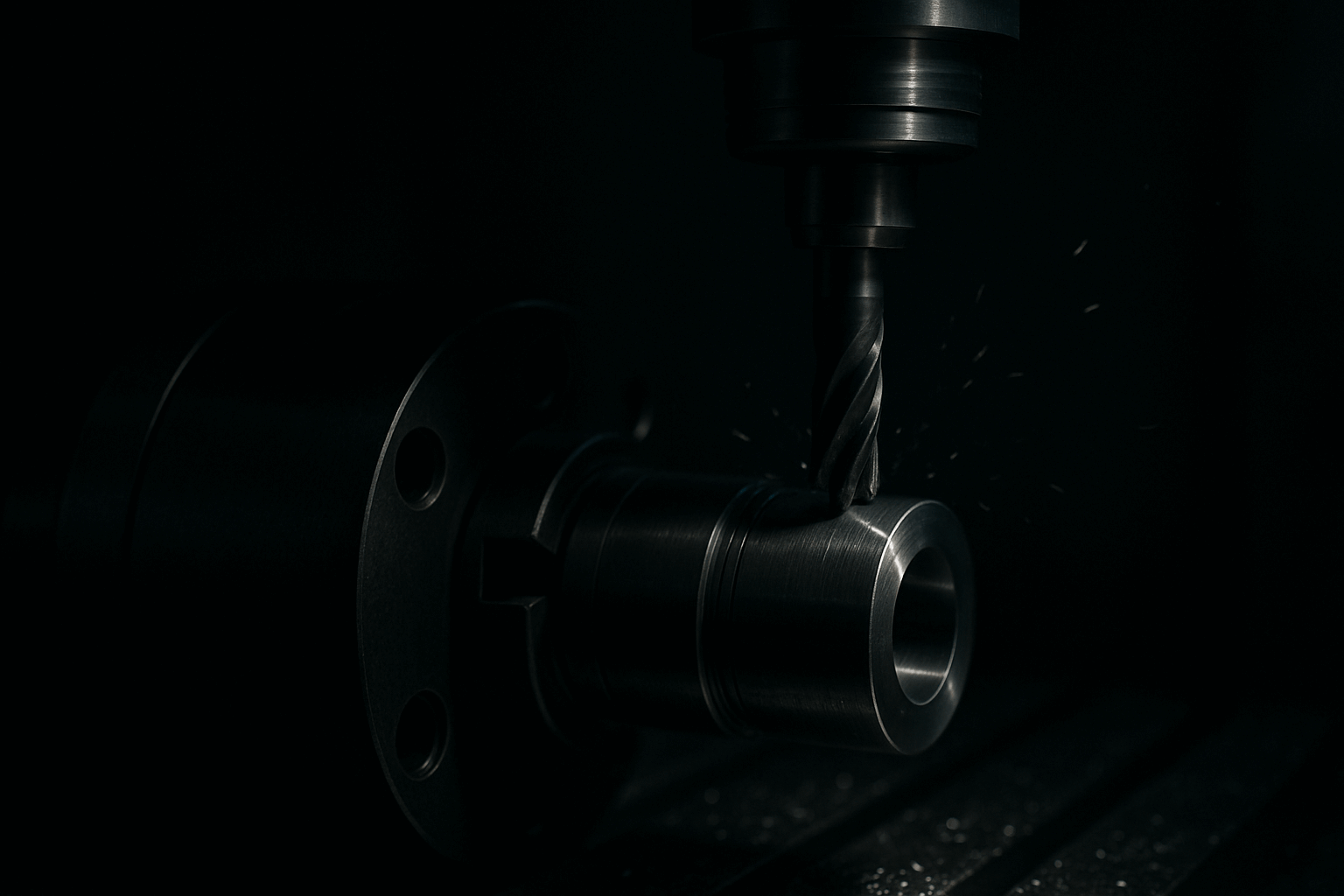

Precision Machining Services

Customization Precision Machining ServicesWe offer a wide range of manufacturing services, including sheet metal processing and precision CNC machining. Our equipment includes advanced CNC machines such as the Lih Mei Sigma9+, Sigma8+, and Chang Ming CMV-6H and CMV-8H, enabling us to produce electronic components, automotive parts, oil circuit systems, semiconductor jigs, and automation equipment components. We specialize in micro-hole machining and high-precision processing, with customizable material options and surface treatments tailored to meet customer requirements.

More

Contact Us Now

Complete online forms and Pin-Jet will have representatives to help you with professional services