Handler Change Kit

Product Description

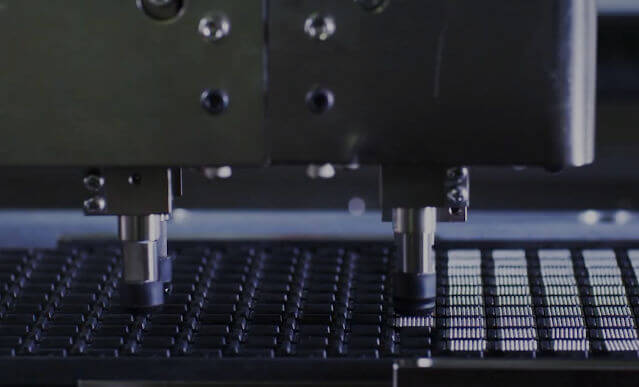

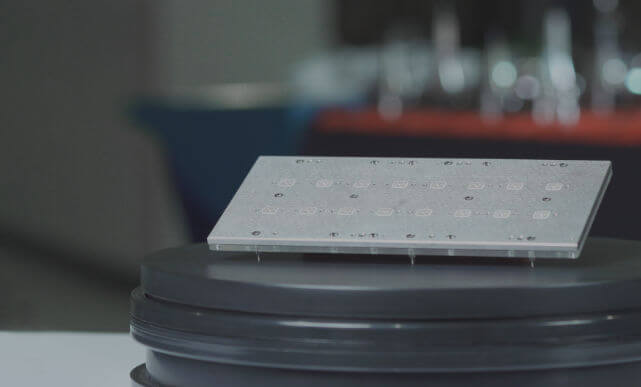

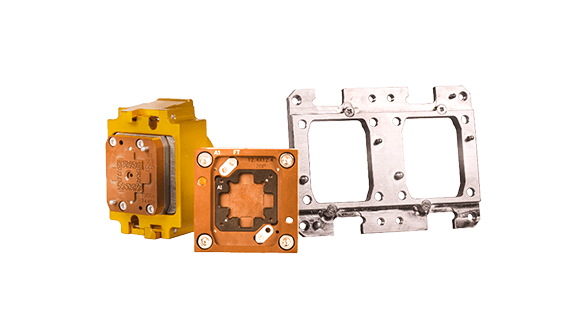

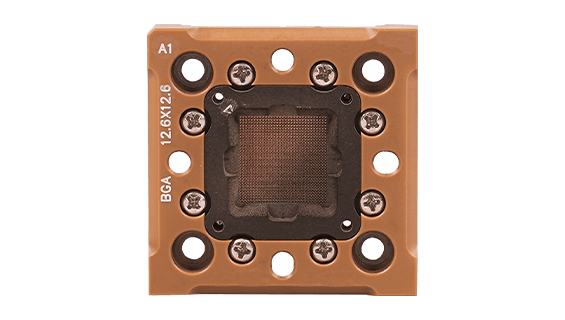

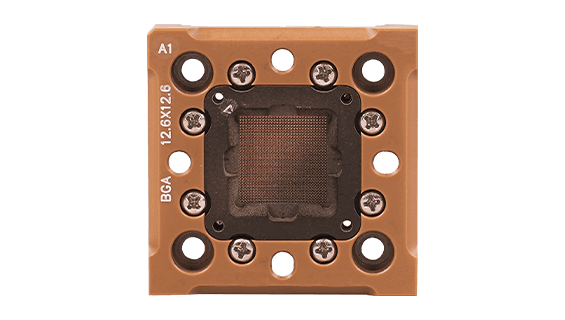

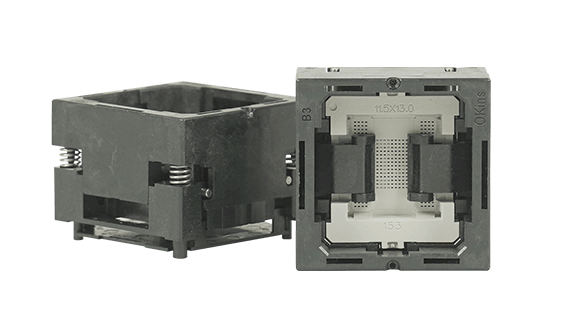

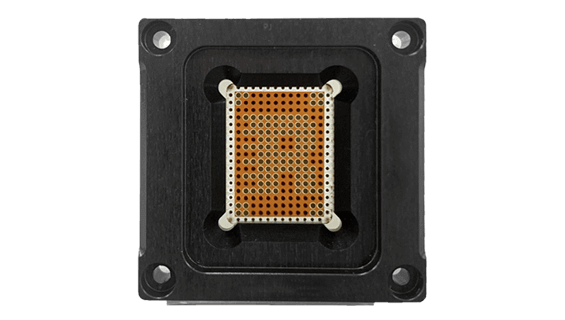

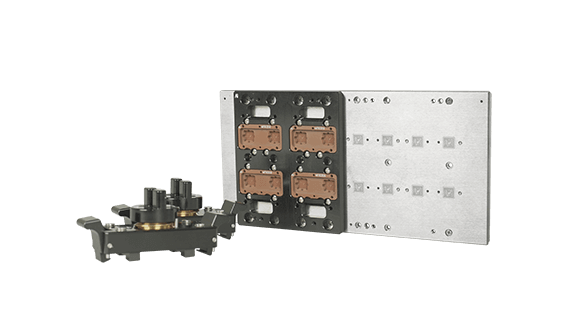

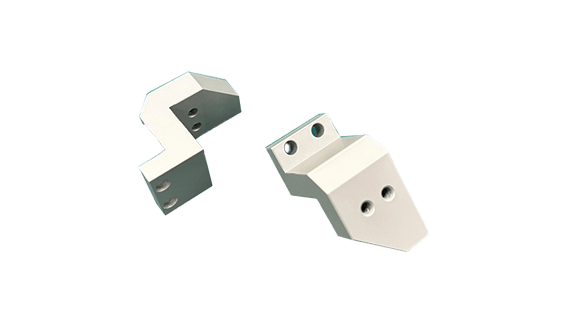

Understanding Handler Change Kits

A Handler Change Kit is a specialized tool that allows automated test equipment (ATE) to accommodate various IC package types. These kits are composed of precisely engineered fixtures or accessories, designed to interact with the tester's handling systems during the testing process. They facilitate the accurate positioning of devices for testing, and ensure their proper sorting into designated storage bins based on test results. This adaptability is essential in semiconductor testing environments where the efficient processing of diverse device types and sizes is critical.

Key Features of Handler Change Kits

Pin-Jet's Handler Change Kit delivers several critical features that establish it as an essential tool in semiconductor manufacturing:

- Adaptability: These kits empower a single test handler to accommodate various device types, enhancing flexibility and reducing overall costs. By facilitating seamless transitions between different test configurations, the Handler Change Kit ensures a versatile testing process and allows for rapid adaptation to diverse devices under test (DUTs).

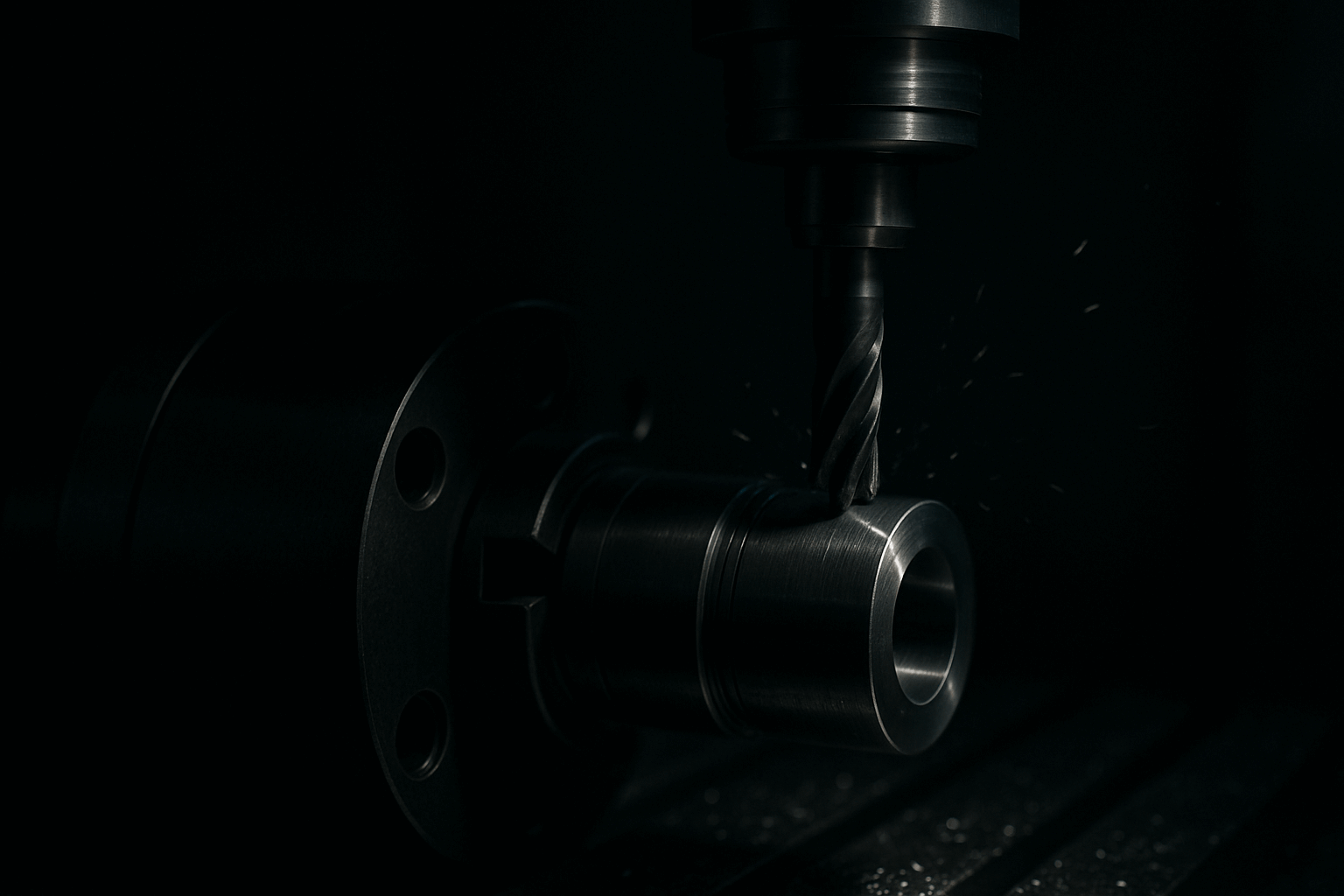

- Precision: The precise and gentle handling of sensitive semiconductor devices is paramount. The Handler Change Kit is meticulously engineered to maintain exceptional accuracy, minimizing the risk of device damage during testing. This precision is vital for acquiring reliable data and maintaining product quality.

- Efficiency: The Handler Change Kit optimizes the testing workflow by enabling swift transitions between different device requirements, thereby reducing downtime and increasing production efficiency. This leads to a more streamlined and cost-effective testing process.

Product Specification

|

Base

|

Hot Plate

|

Shuttle

|

Clamp

|

|---|---|---|---|

|

T6鋁合金,SUS303

|

T6鋁合金

|

T6鋁合金

|

T6鋁合金 , PEEK , TR4230

|

|

-40°C~800°C

|

-40°C~300°C

|

-40°C~300°C

|

-40°C~300°C

|

|

NA

|

10 ~10 Ω/sq

|

10 ~10 Ω/sq

|

10 ~10 Ω/sq

|

|

±0.02mm

|

±0.02mm

|

±0.02mm

|

±0.02mm

|

|

Positioned, Ducking, Fixed L/B & Socket & M/C

|

Pre-Heat, Heating,positioned

|

Pre-Heat, Heating,positioned

|

Pre-Heat, Heating,positioned

|

|

T6 Haed Anodizing

|

EZD 420

|

ESD Coating

|

|---|---|---|

|

T6 Haed Anodizing

|

EZD 420

|

T6鋁合金

|

|

-40°C~800°C

|

-60°C~260°C

|

-60°C~700°C

|

|

1010~1012 Ω/sq

|

106~109Ω/sq

|

106~109Ω/sq

|

|

±0.01mm

|

±0.01mm

|

±0.01mm

|

|

Common use

|

Stable impedance

|

耐磨高導熱

|

MORE PRODUCTS

Contact Us Now

Complete online forms and Pin-Jet will have representatives to help you with professional services