BGA (Ball Grid Array) Soldering Process: Defects and Solutions

The quality of solder balls in the BGA soldering process directly affects the performance and reliability of the product. Various defects, such as voids, bridging, misalignment, and cracks, may occur during the soldering process. These defects can result from factors like soldering materials, equipment parameters, process design, or storage conditions. By optimizing material selection, improving process parameters, and enhancing quality control, the occurrence of soldering defects can be significantly reduced, thereby improving product reliability and lifespan. Below is an analysis of common BGA soldering defects, their causes, and corresponding solutions:

-

Solder Ball Voiding

Issue Description:

Voids appear within the solder joints, potentially affecting the mechanical strength and electrical performance of the joints.

Solutions:

A. Optimize Solder Paste Quality: Select low-void solder paste and thoroughly stir it before use to eliminate air bubbles.

B. Adjust Reflow Profile: Ensure sufficient heating and soaking time to promote complete gas release.

C. Clean Pads and Solder Balls: Use appropriate cleaning agents to remove contaminants and oxidation layers from the pad and solder ball surfaces.

-

Solder Ball Bridging

Issue Description:

Short circuits occur between two or more solder balls, leading to circuit failures.

Solutions:

A. Control Solder Paste Application: Use a stencil with precise thickness to prevent excessive solder paste application.

B. Verify Stencil Alignment: Calibrate the printing machine to ensure the solder paste is applied accurately to the pads.

C. Improve Soldering Process: Adjust the reflow temperature profile to prevent excessive solder flow. -

Solder Ball Cracking

Issue Description:

Cracks appear on the surface or inside the solder balls, which may cause joint failure during use.

Solutions:

A. Choose Compatible Materials: Use solder or substrate materials with a thermal expansion coefficient that matches the PCB.

B. Optimize Cooling Rate: Apply a gradual cooling process after reflow soldering to reduce thermal stress.

C. Avoid External Forces: Minimize excessive mechanical force on the solder joints during testing or assembly. -

Solder Ball Misalignment

Issue Description:

Solder balls are not aligned with the pads, potentially causing poor contact or short circuits of the bga test socket.

Solutions:

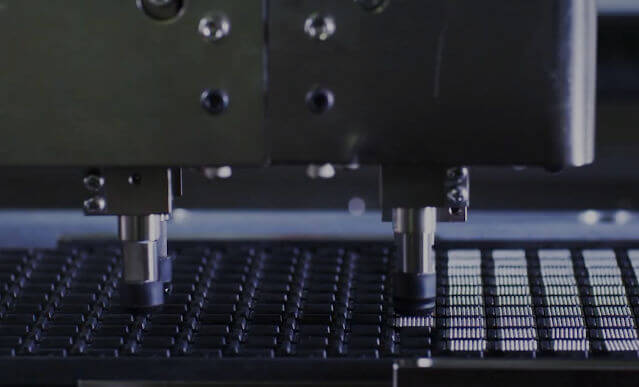

A. Inspect Alignment Equipment: Use high-precision placement machines to ensure accurate alignment between solder balls and pads.

B. Optimize Solder Flow Properties: Choose solder paste with good surface tension to promote automatic alignment of solder to the pads.

C. Improve Reflow Process: Adjust the soldering temperature and time to ensure the solder fully melts and aligns properly with the pads. -

Solder Ball Oxidation

Issue Description:

An oxidation layer forms on the surface of solder balls, reducing solder wetting and conductivity.

Solutions:

A. Improve Storage Conditions: Store BGA packages in a dry box or moisture-proof bags to prevent oxidation.

B. Use Suitable Flux: Select flux with strong deoxidizing properties to enhance solder wetting.

C. Adjust Reflow Atmosphere: Use a nitrogen environment during reflow soldering to minimize the formation of oxides. -

Solder Joint Stress Failure

Issue Description:

Solder joints fail under external force or thermal stress, potentially causing poor electrical contact.

Solutions:

A. Design Stress-Relief Structures: Incorporate stress-relief holes or structures in the PCB design.

B. Use High-Reliability Solder: Select solder with better thermal fatigue resistance.

C. Optimize Testing Conditions: Minimize high temperature and mechanical stress during testing. -

Open Joint

Issue Description:

The solder ball fails to connect with the pad, resulting in an open circuit.

Solutions:

A. Adjust Reflow Profile: Increase the peak temperature or extend the soldering time to ensure the solder fully melts.

B. Clean the Pads: Use cleaning agents to remove contaminants or oxidation layers from the pad surface.

C. Inspect Solder Paste Application: Ensure solder paste is evenly applied to the pads to avoid insufficient coverage that leads to open joints. -

Solder Joint Fatigue

Issue Description:

After prolonged use, solder joints develop cracks or damage, compromising contact reliability.

Solutions:

A. Use High-Reliability Solder: Select solder with added elements such as silver or copper to enhance fatigue resistance.

B. Optimize Solder Joint Design: Reduce stress concentration areas in the solder joint design.

C. Control Operating Conditions: Minimize thermal cycling and mechanical loads on solder joints during operation.

-

Head in Pillow Defect in BGA Soldering Process: Causes and Solutions

2024.12.27

Head in Pillow Defect in BGA Soldering Process: Causes and Solutions

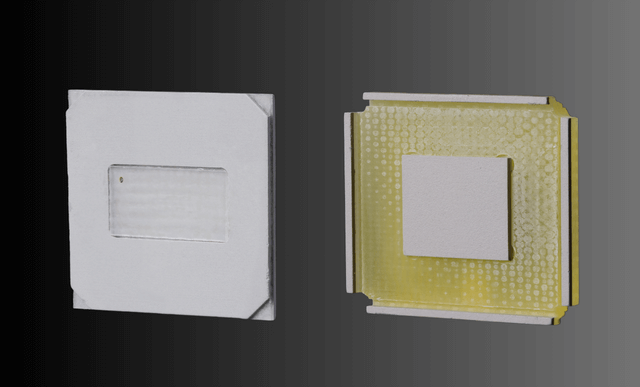

Head-in-Pillow (HIP) is a common failure mode in the BGA (Ball Grid Array) soldering process, referring to incomplete fusion between the BGA solder ball and the PCB pad, resulting in a structure resembling a "pillow and head." This defect can lead to poor contact, affecting the performance and reliability of electronic components.

2024.12.27

Head in Pillow Defect in BGA Soldering Process: Causes and Solutions

Head-in-Pillow (HIP) is a common failure mode in the BGA (Ball Grid Array) soldering process, referring to incomplete fusion between the BGA solder ball and the PCB pad, resulting in a structure resembling a "pillow and head." This defect can lead to poor contact, affecting the performance and reliability of electronic components.

-

Understanding ESD: How It Damages Semiconductor Components and How to Prevent It

2024-12-23

Understanding ESD: How It Damages Semiconductor Components and How to Prevent It

Electrostatic Discharge (ESD) is a phenomenon caused by the transfer of electric charge between two objects that are statically charged. This typically occurs when two objects with different electrical potentials come into contact or are brought close together, resulting in a rapid discharge of static electricity and a sudden flow of current.

2024-12-23

Understanding ESD: How It Damages Semiconductor Components and How to Prevent It

Electrostatic Discharge (ESD) is a phenomenon caused by the transfer of electric charge between two objects that are statically charged. This typically occurs when two objects with different electrical potentials come into contact or are brought close together, resulting in a rapid discharge of static electricity and a sudden flow of current.

-

Wafer Test Probe

2024-12-23

Wafer Test Probe

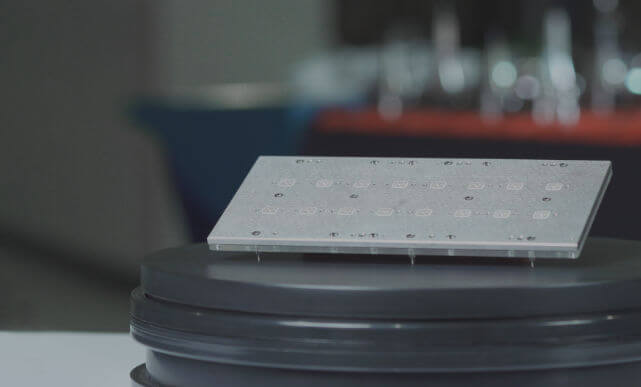

Wafer Testing is an indispensable step in the semiconductor manufacturing process, responsible for inspecting the functionality and performance of each die on a wafer.

2024-12-23

Wafer Test Probe

Wafer Testing is an indispensable step in the semiconductor manufacturing process, responsible for inspecting the functionality and performance of each die on a wafer.

-

How to Clean Pogo Pins: Essential Tips for Effective Maintenance

2024-12-20

How to Clean Pogo Pins: Essential Tips for Effective Maintenance

Pogo Pin is a commonly used spring-loaded probe in semiconductor testing equipment, designed to establish stable electrical connections with electronic components during the testing process. With frequent usage, Pogo Pins are prone to contamination (e.g., oxides, solder residues, or dust), which can result in poor contact and subsequently affect the accuracy and efficiency of testing.

2024-12-20

How to Clean Pogo Pins: Essential Tips for Effective Maintenance

Pogo Pin is a commonly used spring-loaded probe in semiconductor testing equipment, designed to establish stable electrical connections with electronic components during the testing process. With frequent usage, Pogo Pins are prone to contamination (e.g., oxides, solder residues, or dust), which can result in poor contact and subsequently affect the accuracy and efficiency of testing.

-

What is the Final Test in Semiconductor Manufacturing?

2024-06-27

What is the Final Test in Semiconductor Manufacturing?

In the semiconductor manufacturing process, the Final Test (FT) is a critical step that ensures each chip meets the expected performance standards before being shipped.

2024-06-27

What is the Final Test in Semiconductor Manufacturing?

In the semiconductor manufacturing process, the Final Test (FT) is a critical step that ensures each chip meets the expected performance standards before being shipped.

-

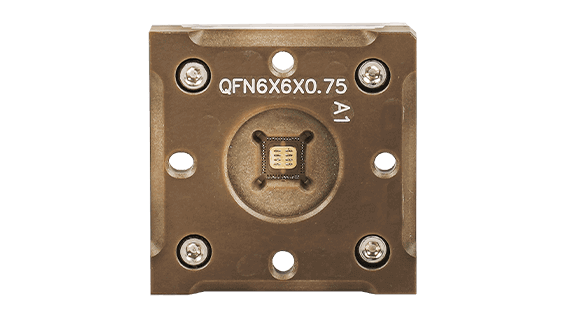

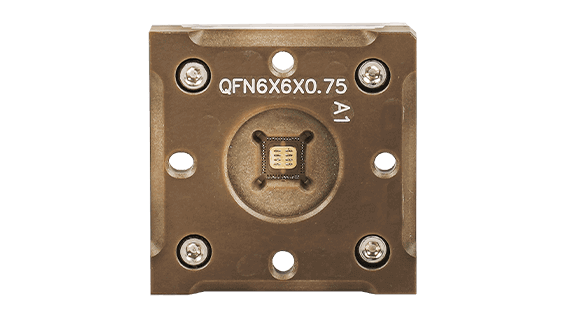

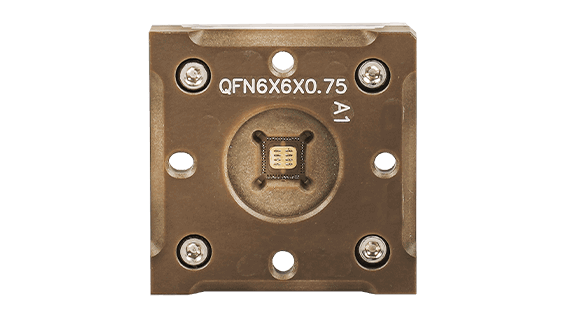

What is a QFN Socket? Key Benefits and Uses

2024-06-12

What is a QFN Socket? Key Benefits and Uses

QFN Socket (Quad Flat No-lead) is a type of leadless surface-mount package used for integrated circuits.

2024-06-12

What is a QFN Socket? Key Benefits and Uses

QFN Socket (Quad Flat No-lead) is a type of leadless surface-mount package used for integrated circuits.

-

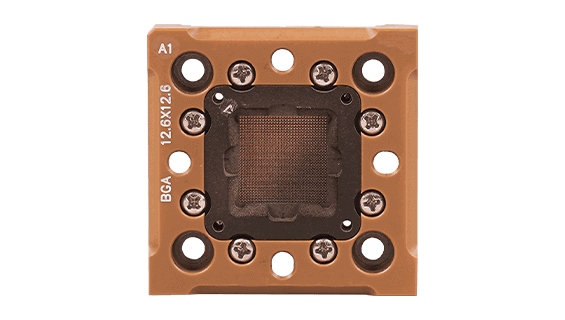

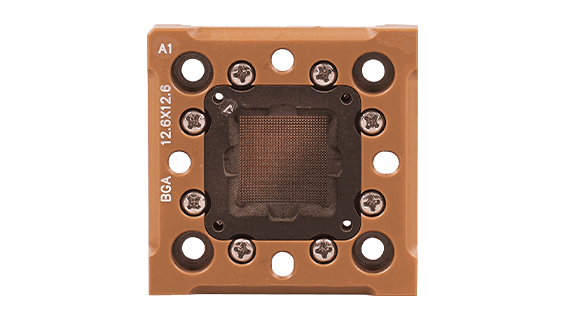

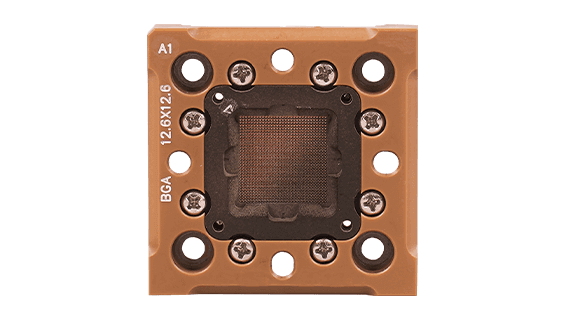

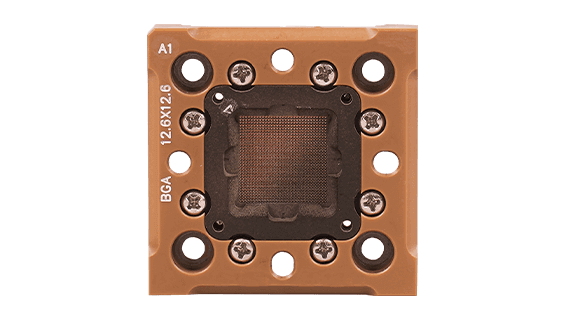

BGA Sockets Basics: Exploring Benefits and Application

2024-06-05

BGA Sockets Basics: Exploring Benefits and Application

A BGA socket (Ball Grid Array socket) is a type of surface mount packaging used for integrated circuits.

2024-06-05

BGA Sockets Basics: Exploring Benefits and Application

A BGA socket (Ball Grid Array socket) is a type of surface mount packaging used for integrated circuits.

-

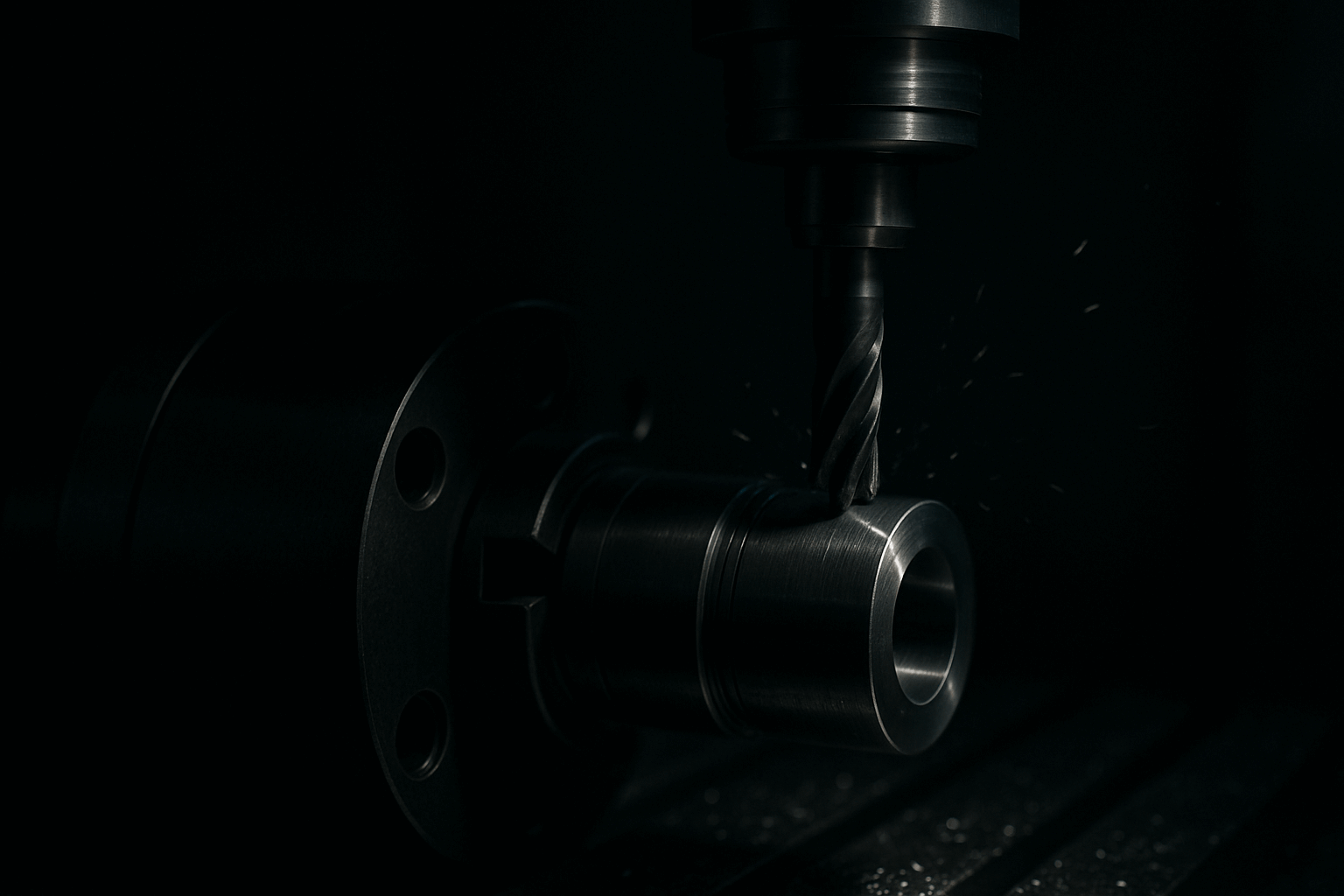

Test Sockets: Key Components in IC Testing

2024-05-29

Test Sockets: Key Components in IC Testing

This article will explore why Test Sockets are important, the different kinds there are, and how they are used in the semiconductor industry.

2024-05-29

Test Sockets: Key Components in IC Testing

This article will explore why Test Sockets are important, the different kinds there are, and how they are used in the semiconductor industry.

Contact Us Now

Complete online forms and Pin-Jet will have representatives to help you with professional services