Test Sockets: Key Components in IC Testing

Introduction

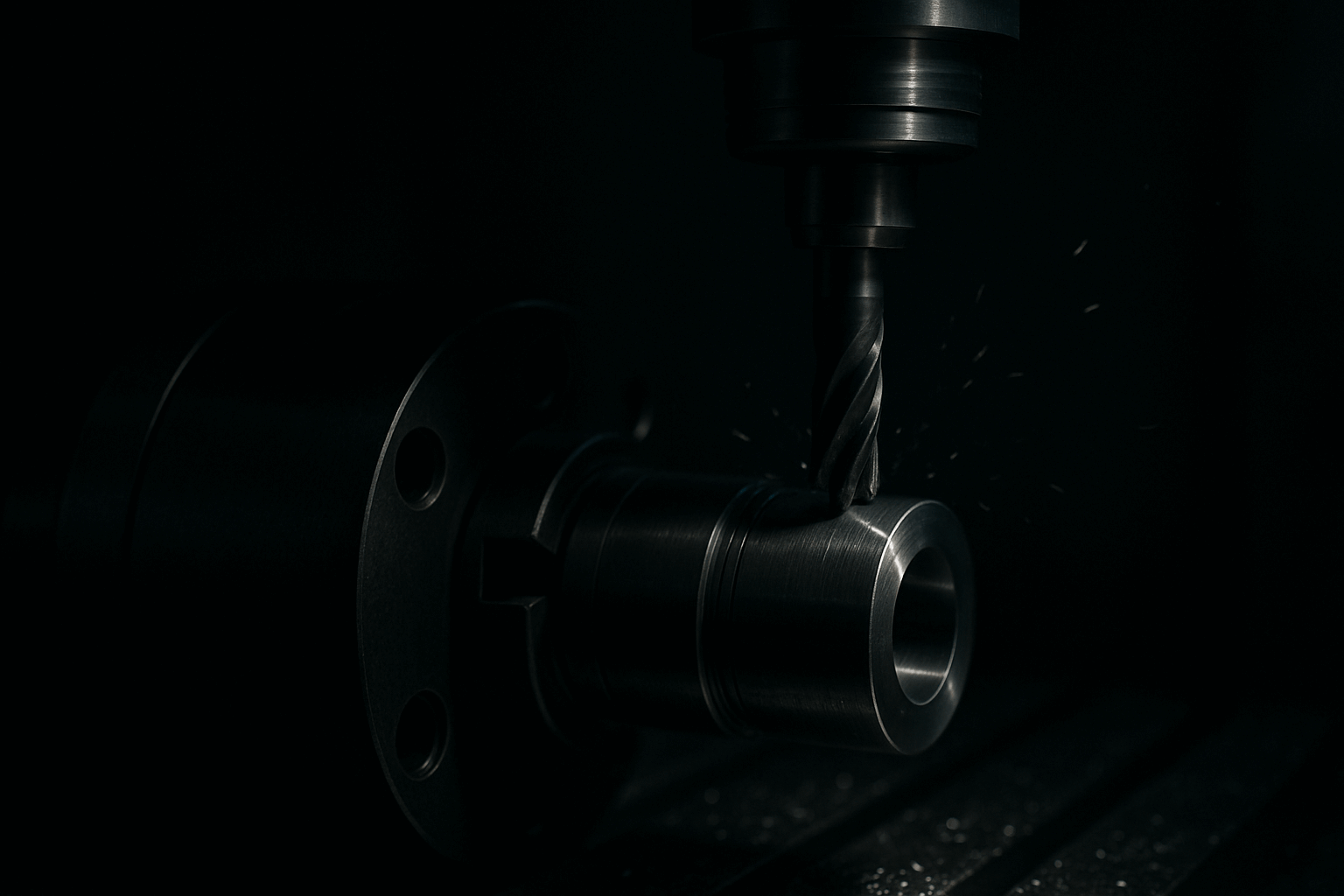

In the rapidly evolving field of semiconductor technology, testing integrated circuits (ICs) is a critical step to ensure their performance, reliability, and functionality. Test sockets play a vital role in this process. This article explores the importance, types, and applications of test sockets in the semiconductor industry.

What are Test Sockets?

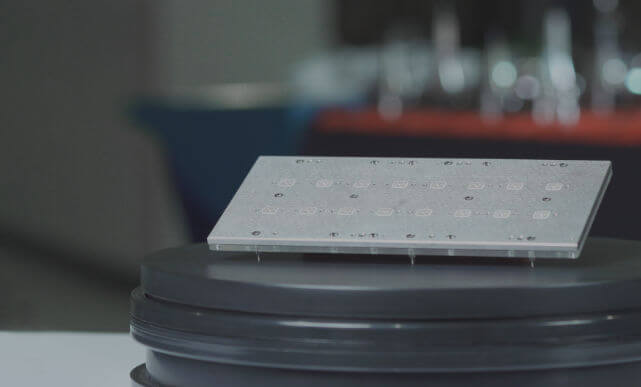

Test sockets are specialized connectors used to temporarily interface ICs with testing equipment during manufacturing and testing stages. They provide a temporary connection between the IC and test hardware, allowing comprehensive testing without permanently mounting the IC onto a circuit board.

Types of Test Sockets

Depending on different testing requirements, there are several types of test sockets :

-

Burn-in Test Sockets

-

Evaluation Sockets

-

Production Test Sockets

-

Debugging Sockets

-

High-Frequency Sockets

Used for reliability testing, burn-in involves prolonged operation of ICs at elevated temperatures and voltages to identify early failures and ensure long-term reliability.

Evaluation sockets are used in the design and development stages of ICs. They allow engineers to test the functionality and performance of prototypes without permanent installation.

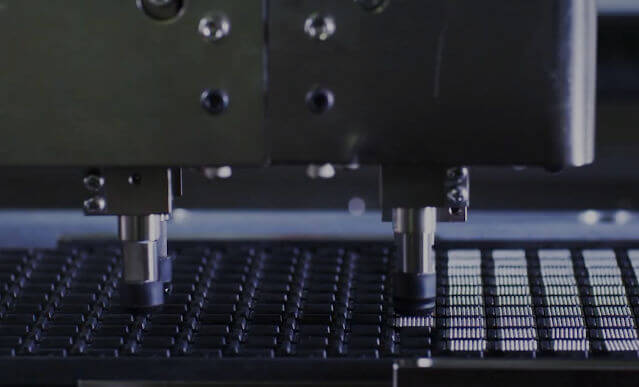

These sockets are used in mass production environments. They are designed for quick and reliable installation and removal of ICs, enhancing efficiency in high-volume testing.

Debugging sockets are used during troubleshooting stages, allowing diagnostic testing and modifications of ICs.

High-frequency sockets are designed for testing ICs operating at high frequencies, ensuring minimal signal loss and maintaining the integrity of high-speed signals.

Key Features of Test Sockets

-

Precision and Accuracy

-

Durability

-

Thermal Management

-

IC Test Socket Compatibility

Test sockets must provide precise and accurate connections to ensure reliable test results. High-quality materials and manufacturing processes are crucial to achieving this goal.

Due to the repetitive nature of IC testing, sockets need to be durable enough to withstand multiple installations and removals without degrading performance.

Effective thermal management is critical, especially for burn-in tests and high-frequency sockets. Good thermal performance prevents overheating and ensures accurate test results.

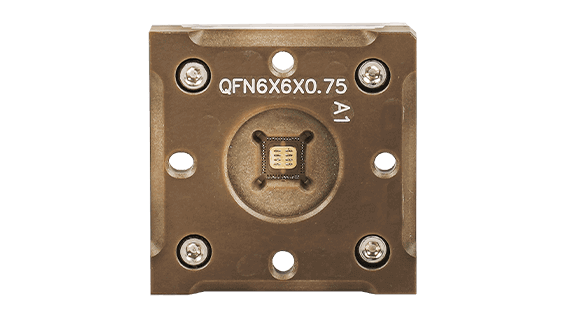

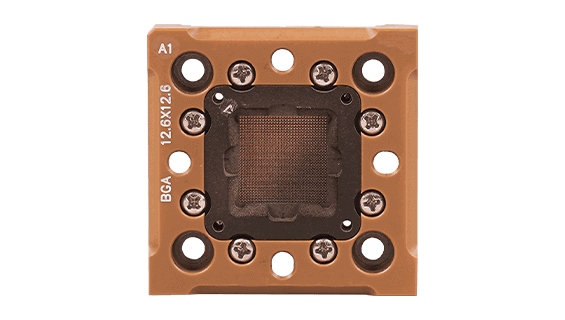

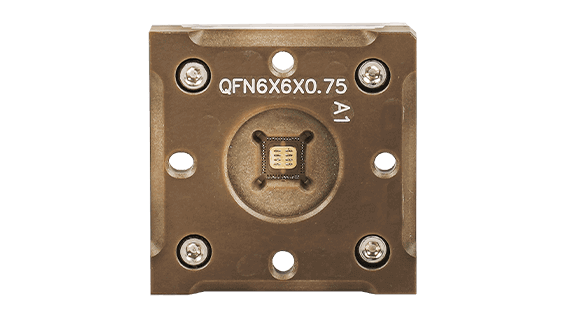

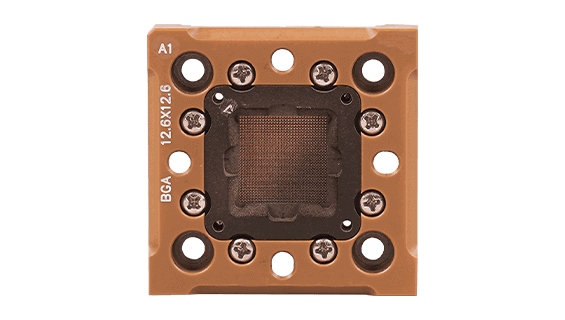

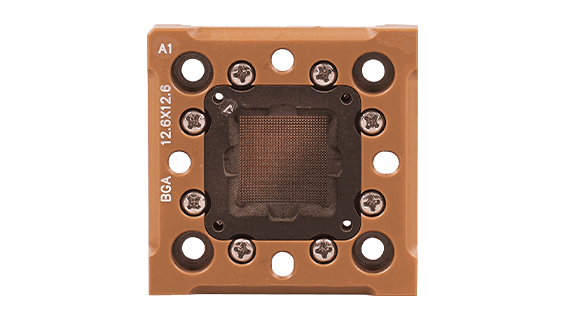

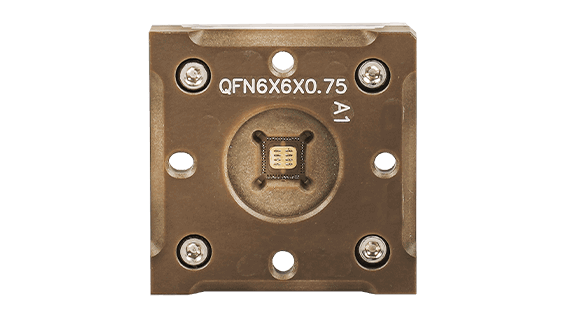

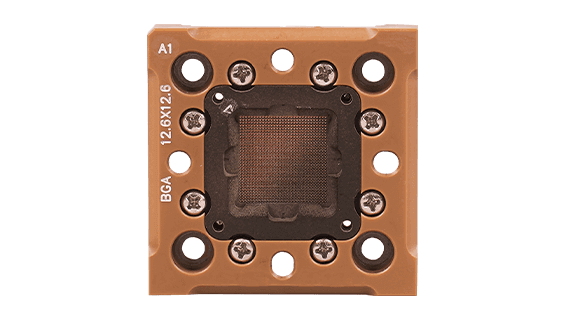

Test sockets must be compatible with various IC packages, including BGA (Ball Grid Array)、 QFN (Quad Flat No-leads) and LGA (Land Grid Array), among others.

Applications of Test Sockets

-

Quality Assurance

-

Research and Development

-

Field Testing

Test sockets are a critical part of quality assurance in the semiconductor manufacturing process. They help identify defects and ensure that only high-quality ICs proceed to the next stage.

In R&D, test sockets enable engineers to experiment with new designs and technologies, providing a flexible and reliable way to prototype testing.

In some scenarios, test sockets are used for field testing to validate IC performance in real-world environments, helping assess IC performance in anticipated application environments.

Conclusion

Semiconductor test sockets are indispensable in IC manufacturing and testing processes. They ensure that ICs meet strict performance and reliability standards required by today's advanced electronic devices. By providing a stable connection between ICs and testing equipment, test sockets assist manufacturers in delivering high-quality products to the market. As semiconductor technology continues to evolve, the importance of test sockets in maintaining quality and innovation will remain paramount.

-

Head in Pillow Defect in BGA Soldering Process: Causes and Solutions

2024.12.27

Head in Pillow Defect in BGA Soldering Process: Causes and Solutions

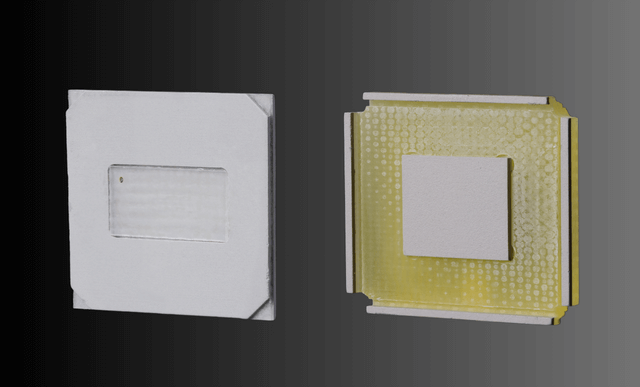

Head-in-Pillow (HIP) is a common failure mode in the BGA (Ball Grid Array) soldering process, referring to incomplete fusion between the BGA solder ball and the PCB pad, resulting in a structure resembling a "pillow and head." This defect can lead to poor contact, affecting the performance and reliability of electronic components.

2024.12.27

Head in Pillow Defect in BGA Soldering Process: Causes and Solutions

Head-in-Pillow (HIP) is a common failure mode in the BGA (Ball Grid Array) soldering process, referring to incomplete fusion between the BGA solder ball and the PCB pad, resulting in a structure resembling a "pillow and head." This defect can lead to poor contact, affecting the performance and reliability of electronic components.

-

Understanding ESD: How It Damages Semiconductor Components and How to Prevent It

2024-12-23

Understanding ESD: How It Damages Semiconductor Components and How to Prevent It

Electrostatic Discharge (ESD) is a phenomenon caused by the transfer of electric charge between two objects that are statically charged. This typically occurs when two objects with different electrical potentials come into contact or are brought close together, resulting in a rapid discharge of static electricity and a sudden flow of current.

2024-12-23

Understanding ESD: How It Damages Semiconductor Components and How to Prevent It

Electrostatic Discharge (ESD) is a phenomenon caused by the transfer of electric charge between two objects that are statically charged. This typically occurs when two objects with different electrical potentials come into contact or are brought close together, resulting in a rapid discharge of static electricity and a sudden flow of current.

-

Wafer Test Probe

2024-12-23

Wafer Test Probe

Wafer Testing is an indispensable step in the semiconductor manufacturing process, responsible for inspecting the functionality and performance of each die on a wafer.

2024-12-23

Wafer Test Probe

Wafer Testing is an indispensable step in the semiconductor manufacturing process, responsible for inspecting the functionality and performance of each die on a wafer.

-

How to Clean Pogo Pins: Essential Tips for Effective Maintenance

2024-12-20

How to Clean Pogo Pins: Essential Tips for Effective Maintenance

Pogo Pin is a commonly used spring-loaded probe in semiconductor testing equipment, designed to establish stable electrical connections with electronic components during the testing process. With frequent usage, Pogo Pins are prone to contamination (e.g., oxides, solder residues, or dust), which can result in poor contact and subsequently affect the accuracy and efficiency of testing.

2024-12-20

How to Clean Pogo Pins: Essential Tips for Effective Maintenance

Pogo Pin is a commonly used spring-loaded probe in semiconductor testing equipment, designed to establish stable electrical connections with electronic components during the testing process. With frequent usage, Pogo Pins are prone to contamination (e.g., oxides, solder residues, or dust), which can result in poor contact and subsequently affect the accuracy and efficiency of testing.

-

BGA (Ball Grid Array) Soldering Process: Defects and Solutions

2024-12-20

BGA (Ball Grid Array) Soldering Process: Defects and Solutions

The quality of solder balls in the BGA soldering process directly affects the performance and reliability of the product. Various defects, such as voids, bridging, misalignment, and cracks, may occur during the soldering process. These defects can result from factors like soldering materials, equipment parameters, process design, or storage conditions. By optimizing material selection, improving process parameters, and enhancing quality control, the occurrence of soldering defects can be significantly reduced, thereby improving product reliability and lifespan.

2024-12-20

BGA (Ball Grid Array) Soldering Process: Defects and Solutions

The quality of solder balls in the BGA soldering process directly affects the performance and reliability of the product. Various defects, such as voids, bridging, misalignment, and cracks, may occur during the soldering process. These defects can result from factors like soldering materials, equipment parameters, process design, or storage conditions. By optimizing material selection, improving process parameters, and enhancing quality control, the occurrence of soldering defects can be significantly reduced, thereby improving product reliability and lifespan.

-

What is the Final Test in Semiconductor Manufacturing?

2024-06-27

What is the Final Test in Semiconductor Manufacturing?

In the semiconductor manufacturing process, the Final Test (FT) is a critical step that ensures each chip meets the expected performance standards before being shipped.

2024-06-27

What is the Final Test in Semiconductor Manufacturing?

In the semiconductor manufacturing process, the Final Test (FT) is a critical step that ensures each chip meets the expected performance standards before being shipped.

-

What is a QFN Socket? Key Benefits and Uses

2024-06-12

What is a QFN Socket? Key Benefits and Uses

QFN Socket (Quad Flat No-lead) is a type of leadless surface-mount package used for integrated circuits.

2024-06-12

What is a QFN Socket? Key Benefits and Uses

QFN Socket (Quad Flat No-lead) is a type of leadless surface-mount package used for integrated circuits.

-

BGA Sockets Basics: Exploring Benefits and Application

2024-06-05

BGA Sockets Basics: Exploring Benefits and Application

A BGA socket (Ball Grid Array socket) is a type of surface mount packaging used for integrated circuits.

2024-06-05

BGA Sockets Basics: Exploring Benefits and Application

A BGA socket (Ball Grid Array socket) is a type of surface mount packaging used for integrated circuits.

Contact Us Now

Complete online forms and Pin-Jet will have representatives to help you with professional services