2024/01/11

Successful Stories

SB5XXX LDO Item Test Fail

Pin-Jet helped the customer determine why the LDO item failed

The customer gave the feedback that the LDO item failed easily; after manual testing, it was confirmed that it passed stably with no LDO item fails. After Pin-Jet aligned with the customer, problems with the LDO item occurred easily when contact mool was used; after confirming, it was found that the reason was because the customer had insufficient clamp force, which caused poor contact.

Problem Description

✔ Incident: Yi SB5XXX LDO Item Test Fail

✔ Target: Solve the part tested to be abnormal

Problem Confirmation

✔ Pin Mark Check → PASS

✔ FDR Check → PASS

✔ Accessory combination tolerance Check → PASS

On-site Verification Cover test / Contact test:

✔ Cover Test Loop 20次 → PASS

✔ Contact Test → Fail

Design Experiments and Verify Implementation

Purpose: Verify the mismatch between the spring inside the feedback clamp and the socket force, and improve the contact test so that it can pass stably.

Method: Change the original 3.52KG spring to a 4KG spring and verify the contact.

Experiment conditions:

1. By Corr Sample experiment using the same site

2. Use 3.52KG for Arm 1 Clamp

3. Use 4KG for Arm 2 Clamp

✔ Use the original 3.52KG spring for Arm 1:

✔ Install the 4KG spring for Arm 2 and verify that the loop passed 20 times stably:

Conclusion: It was confirmed that the contact test could pass stably after replacing with a 4KG spring.

Related News

-

Clean Pad Implementation Results – Extended Test Lifetime & Improved First Yield

2025/07/02

Clean Pad Implementation Results – Extended Test Lifetime & Improved First Yield

In this case, a CST socket was selected as the Clean Pad implementation target. Through continuous testing, we compared first yield and the effect of Touchdown count on pin performance before and after Clean Pad adoption.

2025/07/02

Clean Pad Implementation Results – Extended Test Lifetime & Improved First Yield

In this case, a CST socket was selected as the Clean Pad implementation target. Through continuous testing, we compared first yield and the effect of Touchdown count on pin performance before and after Clean Pad adoption.

-

Product ICI Fail & Pin Low Life Time

2024/01/11

Product ICI Fail & Pin Low Life Time

Although the pin tip was not blunted, but when analyzed through related instruments such as X-ray and FDR, it was discovered that the gold plating layer at the end of the pin had peeled off, which could easily cause ICI Fail.

2024/01/11

Product ICI Fail & Pin Low Life Time

Although the pin tip was not blunted, but when analyzed through related instruments such as X-ray and FDR, it was discovered that the gold plating layer at the end of the pin had peeled off, which could easily cause ICI Fail.

-

Socket SB21512 Fail Issue

2024/01/11

Socket SB21512 Fail Issue

3ea socket had SB21512 Fail during NPI engineering, and the true cause could not be found. Pin-Jet helped discover that the customer’s socket had wetting; however, after cleaned, reinstalled and tested, the abnormality still occurred. We cross-checked with another Corr IC and the manual test passed. It was confirmed that the read value of this Corr IC that had this abnormality easily was higher compared to the Corr IC that passed.

2024/01/11

Socket SB21512 Fail Issue

3ea socket had SB21512 Fail during NPI engineering, and the true cause could not be found. Pin-Jet helped discover that the customer’s socket had wetting; however, after cleaned, reinstalled and tested, the abnormality still occurred. We cross-checked with another Corr IC and the manual test passed. It was confirmed that the read value of this Corr IC that had this abnormality easily was higher compared to the Corr IC that passed.

-

SLT Test Low Yield

2024/01/11

SLT Test Low Yield

The customer gave the feedback that the Pin Life time was approximately 70K; after confirmation by Pin-Jet, it was discovered that when the same PCB & socket was reassembled multiple times, the test results of each manual test were different. After investigation, it was found that the PCB pad was punctured and necessary to be replaced.

2024/01/11

SLT Test Low Yield

The customer gave the feedback that the Pin Life time was approximately 70K; after confirmation by Pin-Jet, it was discovered that when the same PCB & socket was reassembled multiple times, the test results of each manual test were different. After investigation, it was found that the PCB pad was punctured and necessary to be replaced.

-

Clean Pad Drop Error Abnormality

2024/01/11

Clean Pad Drop Error Abnormality

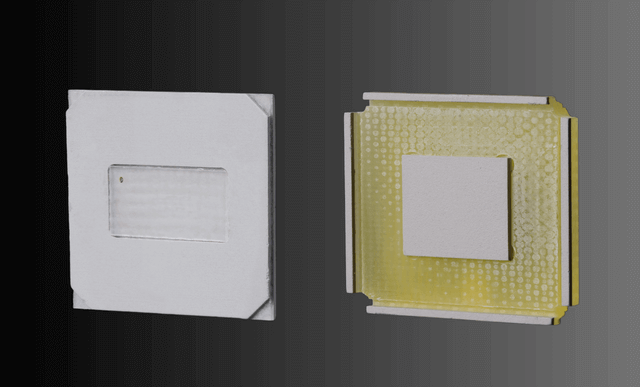

The customer gave the feedback that the clean pad would not fall after the vacuum in the NEST was broken; after confirmation by Pin-Jet, it was found that there was inverted round corners inside the NEST, but the clean pad had a right-angle exterior, which caused interference.

2024/01/11

Clean Pad Drop Error Abnormality

The customer gave the feedback that the clean pad would not fall after the vacuum in the NEST was broken; after confirmation by Pin-Jet, it was found that there was inverted round corners inside the NEST, but the clean pad had a right-angle exterior, which caused interference.

Contact Us Now

Complete online forms and Pin-Jet will have representatives to help you with professional services