Product ICI Fail & Pin Low Life Time

Help the customer find out the reason for poor test yield

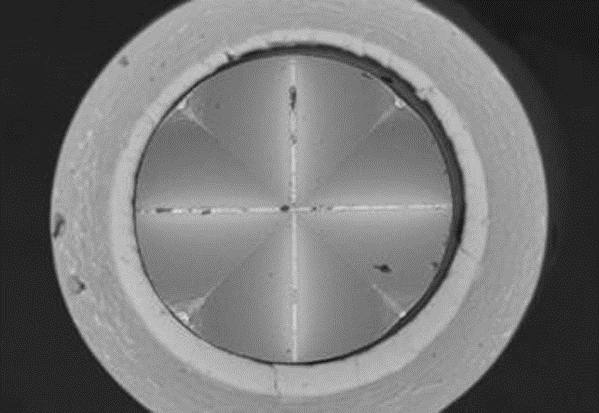

Although the pin tip was not blunted, but when analyzed through related instruments such as X-ray and FDR, it was discovered that the gold plating layer at the end of the pin had peeled off, which could easily cause ICI Fail.

Problem Description

✔Solve the abnormal user pin problem

A certain test result captured by the user:

ICI Fail occurred a total of eight times;

LINUX fail occurred a total of five times.

Test result

Problem Confirmation

- The gold plating layer at the end of the pin is suspected of peeling due to external force.

- Although the pin spring is at a normal value, but it seems to be declining slowly.

- The head of the pin is suspected of changing color due to high current and high temperature.

- The machine press did not return; it is suspected of having poor contact.

- The contact stroke had an over-voltage of 0.38mm after calculation.(measured with actual object)

- The SLT socket was tested manually and verified with FT and passed.

Pogo Pin Analysis

1. The gold plating layer at the end of the pin is suspected of peeling due to external force.

2. The head of the pin is suspected of changing color due to a high current and high temperature.

3. Although the pin spring is within the normal value, it seems to be declining slowly.

The maximum current value of a single pin must be confirmed in order to analyze the reason why the color change of the pin head and spring are gradually declining.

The pin manufacturer measured and replied that there is no reaming between the top plunger & barrel.

Current Condition of the Machine Contact

4. The machine press did not return; it is suspected of having poor contact.

The gaps between the chuck and IC and base are smaller.

The gaps between the chuck and IC and

base are larger, and can easily have the concern of poor contact.

The heights measured at the two site chucks are 4.76 and 4.78

The heights measured at the two site chucks are 4.76 and 4.78

Contact Stroke Confirmation

5. It was found that the contact stroke had an over-voltage of 0.38mm after calculation. (measured with actual object)

IC colloid thickness: 2.32mm + Chuck height: 4.76mm = 7.08mm

Socket depth: 4.2mm + Base thickness:2.50mm = 6.7mm

7.08mm - 6.7mm = 0.38mm

Contact Simulation Diagram

If the IC height is a simulation diagram of the maximum value, the result is over-pressure by 0.48mm.

IC colloid thickness:2.42mm + Chuck height:4.76mm = 7.18mm

Socket depth:4.2mm + Base thickness: 2.50mm = 6.7mm

7.18mm - 6.7mm = 0.48mm

The SLT Socket Was Tested Manually and Verified With FT

6. The SLT socket was tested manually and verified with FT and passed.

The results of the manual testing and verification of the socket are as follows:

The SLT socket that has ICI Fail easily was tested manually with the FT machine and passed.

-

Clean Pad Implementation Results – Extended Test Lifetime & Improved First Yield

2025/07/02

Clean Pad Implementation Results – Extended Test Lifetime & Improved First Yield

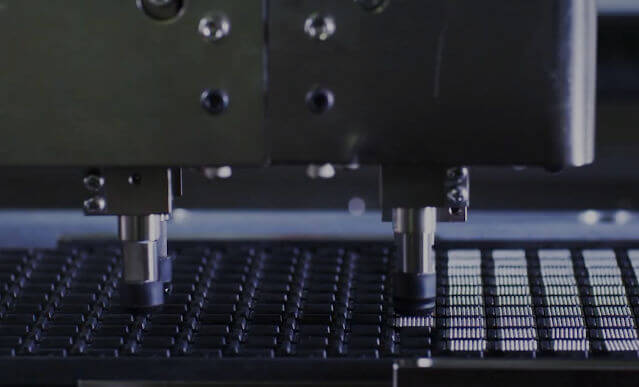

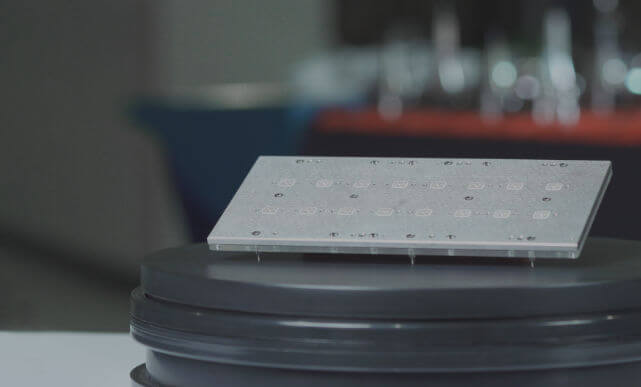

In this case, a CST socket was selected as the Clean Pad implementation target. Through continuous testing, we compared first yield and the effect of Touchdown count on pin performance before and after Clean Pad adoption.

2025/07/02

Clean Pad Implementation Results – Extended Test Lifetime & Improved First Yield

In this case, a CST socket was selected as the Clean Pad implementation target. Through continuous testing, we compared first yield and the effect of Touchdown count on pin performance before and after Clean Pad adoption.

-

Socket SB21512 Fail Issue

2024/01/11

Socket SB21512 Fail Issue

3ea socket had SB21512 Fail during NPI engineering, and the true cause could not be found. Pin-Jet helped discover that the customer’s socket had wetting; however, after cleaned, reinstalled and tested, the abnormality still occurred. We cross-checked with another Corr IC and the manual test passed. It was confirmed that the read value of this Corr IC that had this abnormality easily was higher compared to the Corr IC that passed.

2024/01/11

Socket SB21512 Fail Issue

3ea socket had SB21512 Fail during NPI engineering, and the true cause could not be found. Pin-Jet helped discover that the customer’s socket had wetting; however, after cleaned, reinstalled and tested, the abnormality still occurred. We cross-checked with another Corr IC and the manual test passed. It was confirmed that the read value of this Corr IC that had this abnormality easily was higher compared to the Corr IC that passed.

-

SLT Test Low Yield

2024/01/11

SLT Test Low Yield

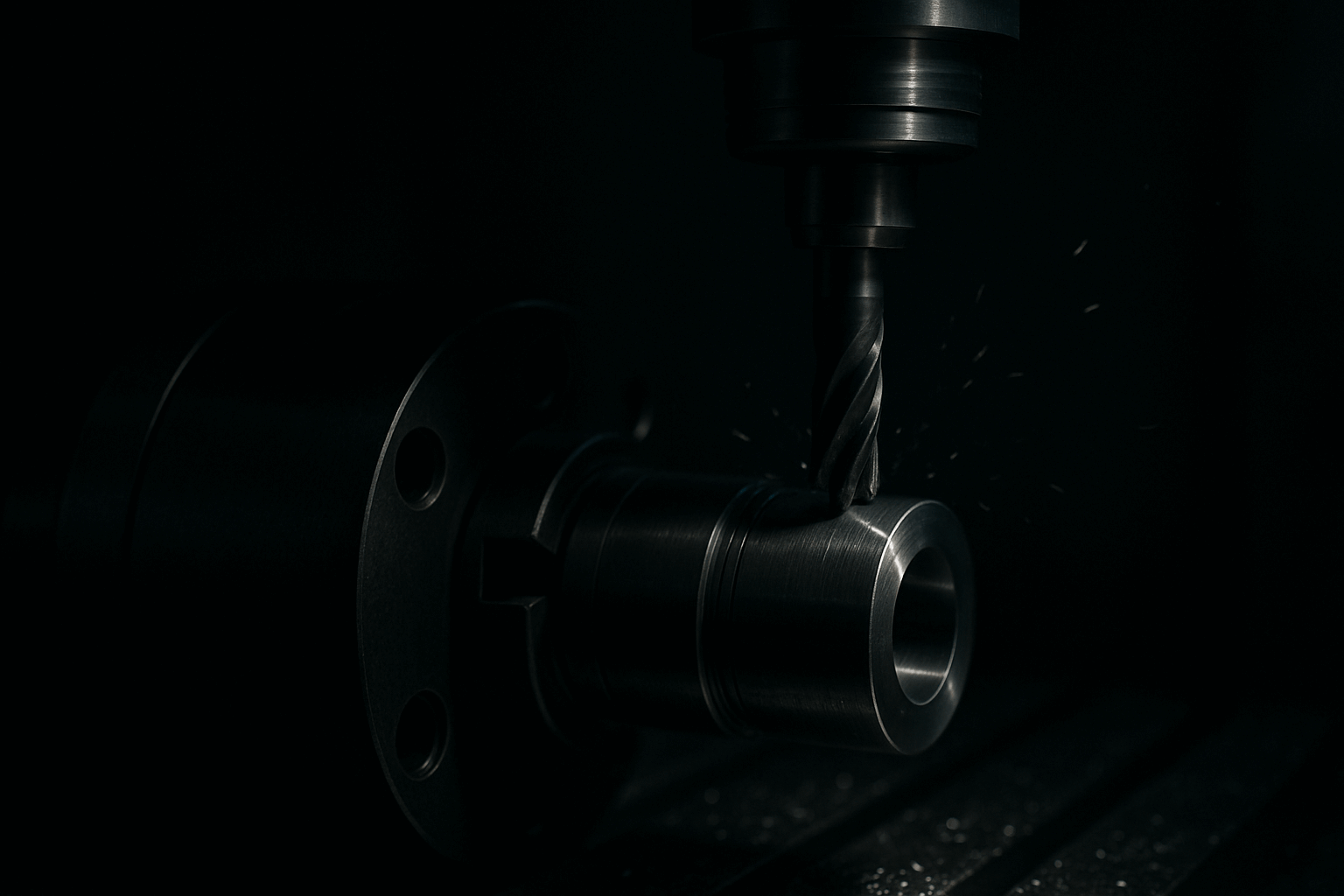

The customer gave the feedback that the Pin Life time was approximately 70K; after confirmation by Pin-Jet, it was discovered that when the same PCB & socket was reassembled multiple times, the test results of each manual test were different. After investigation, it was found that the PCB pad was punctured and necessary to be replaced.

2024/01/11

SLT Test Low Yield

The customer gave the feedback that the Pin Life time was approximately 70K; after confirmation by Pin-Jet, it was discovered that when the same PCB & socket was reassembled multiple times, the test results of each manual test were different. After investigation, it was found that the PCB pad was punctured and necessary to be replaced.

-

SB5XXX LDO Item Test Fail

2024/01/11

SB5XXX LDO Item Test Fail

The customer gave the feedback that the LDO item failed easily; after manual testing, it was confirmed that it passed stably with no LDO item fails. After Pin-Jet aligned with the customer, problems with the LDO item occurred easily when contact mool was used; after confirming, it was found that the reason was because the customer had insufficient clamp force, which caused poor contact.

2024/01/11

SB5XXX LDO Item Test Fail

The customer gave the feedback that the LDO item failed easily; after manual testing, it was confirmed that it passed stably with no LDO item fails. After Pin-Jet aligned with the customer, problems with the LDO item occurred easily when contact mool was used; after confirming, it was found that the reason was because the customer had insufficient clamp force, which caused poor contact.

-

Clean Pad Drop Error Abnormality

2024/01/11

Clean Pad Drop Error Abnormality

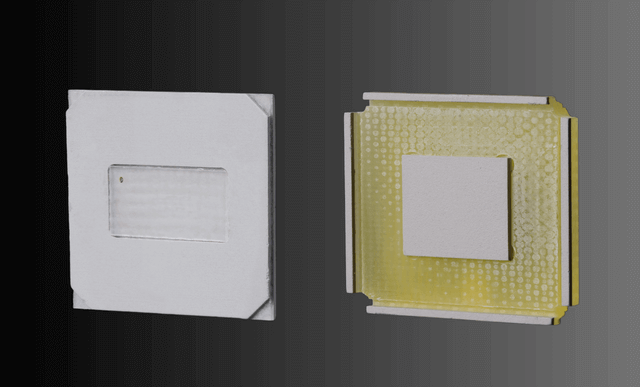

The customer gave the feedback that the clean pad would not fall after the vacuum in the NEST was broken; after confirmation by Pin-Jet, it was found that there was inverted round corners inside the NEST, but the clean pad had a right-angle exterior, which caused interference.

2024/01/11

Clean Pad Drop Error Abnormality

The customer gave the feedback that the clean pad would not fall after the vacuum in the NEST was broken; after confirmation by Pin-Jet, it was found that there was inverted round corners inside the NEST, but the clean pad had a right-angle exterior, which caused interference.

Contact Us Now

Complete online forms and Pin-Jet will have representatives to help you with professional services