Clean Pad Implementation Results – Extended Test Lifetime & Improved First Yield

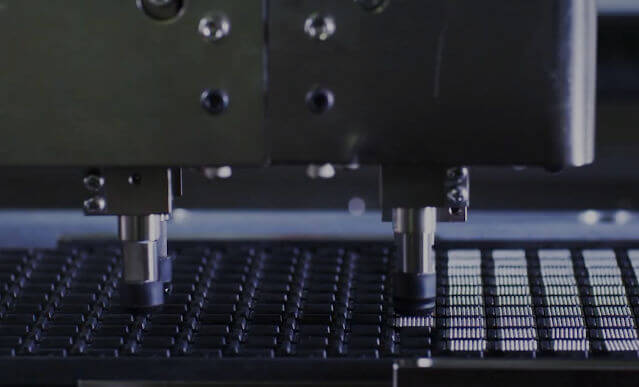

Why Use Clean Pad?

During long-term testing, pin tips are prone to contamination such as tin adhesion or carbon buildup, which may trigger eutectic reactions and result in a decline in first yield.

In this case, a CST socket was selected as the Clean Pad implementation target. Through continuous testing, we compared first yield and the effect of Touchdown count on pin performance before and after Clean Pad adoption.

Before Using Clean Pad:

- After approximately 64K touchdowns, offline cleaning was required every 15K–30K touchdowns.

- After exceeding 200K touchdowns, test performance significantly degraded, and pins could no longer be used—complete pin replacement was required.

- Before reaching 230K touchdowns, offline pin cleaning was conducted seven times due to low yield.

- Pin tips were visibly worn and dulled.

|

Clean Time

|

Touch Down

|

Test Stage

|

Remark

|

|---|---|---|---|

|

1st Pin Cleaning

|

64.5K

|

After FT3

|

Low Yield (79.54%,55.3%) due to RT

|

|

2nd Pin Cleaning

|

86.5K

|

After FT3

|

Low Yield (….) due to RT

|

|

3rd Pin Cleaning

|

95.5K

|

FT1

|

Low Yield due to contact issue

|

|

4th Pin Cleaning

|

104.2K

|

FT1

|

Low Yield due to contact issue

|

|

5th Pin Cleaning

|

132.5K

|

FT1

|

Low Yield due to contact issue

|

|

6th Pin Cleaning

|

162.5K

|

After FT2

|

Self-initiated pin cleaning

|

|

7th Pin Cleaning

|

189.5K

|

After FT3

|

Self-initiated pin cleaning

|

|

8th Pin Cleaning

|

201.1K

|

FT1

|

Low Yield due to contact issue

|

|

9th Pin Cleaning

|

230K

|

FT1

|

Low Yield (….) due to RT

|

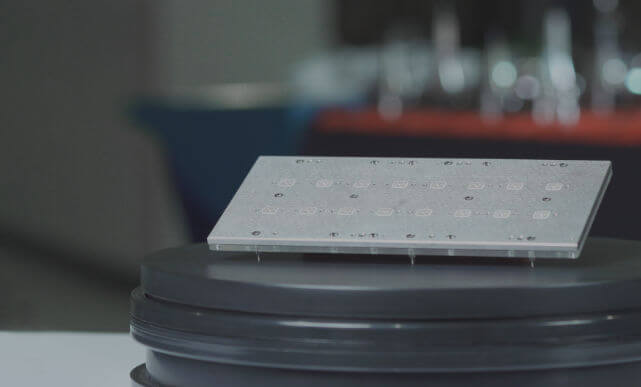

After Implementing Clean Pad:

- Prior to 230K touchdowns, all cleanings were performed automatically after high-temperature testing, with no offline cleaning required due to low yield.

- Offline cleaning only began after 235K touchdowns, triggered by elevated Ron resistance.

- Before reaching 300K touchdowns, cleaning due to low yield occurred only three times

- At 297K touchdowns, the pins remained in good condition, with no noticeable blunting observed.

|

Clean Time

|

Touch Down

|

Test Stage

|

Remark

|

|---|---|---|---|

|

1st Pin Cleaning

|

49.7K

|

After FT2

|

Self-initiated pin cleaning

|

|

2nd Pin Cleaning

|

133.7K

|

After FT2

|

After self-initiated pin cleaning, a Clean Pad experiment was conducted at 9.8K touchdowns.

|

|

3rd Pin Cleaning

|

159.4K

|

After FT3

|

Automatic pin cleaning performed after high-temperature testing.

|

|

4th Pin Cleaning

|

222.6K

|

After FT3

|

Automatic pin cleaning performed after high-temperature testing.

|

|

5th Pin Cleaning

|

236.2K

|

After FT1

|

FT2 low yield (impedance too high)

|

|

6th Pin Cleaning

|

267K

|

After FT3

|

Automatic pin cleaning performed after high-temperature testing.

|

|

7th Pin Cleaning

|

278.3K

|

FT2

|

FT2 low yield (impedance too high)

|

|

8th Pin Cleaning

|

293K

|

FT2

|

FT2 low yield (impedance too high)

|

Conclusion:

The implementation of Clean Pad has been highly recognized by the customer. Based on actual test data, the current pin lifespan has increased by over 70K touchdowns and continues to improve. Yield retention remains stable, indicating a significant extension in pin testing life and a noticeable reduction in contact failures.

Additionally, the number of offline cleaning sessions has been greatly reduced.

For customers focusing on automated testing, mass production, and enhanced test efficiency, Clean Pad proves to be a reliable and valuable auxiliary solution.

-

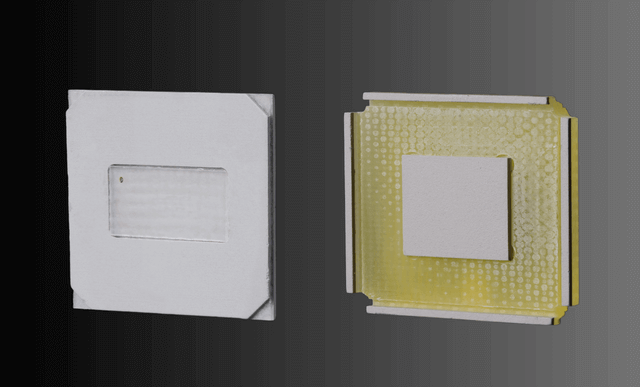

Product ICI Fail & Pin Low Life Time

2024/01/11

Product ICI Fail & Pin Low Life Time

Although the pin tip was not blunted, but when analyzed through related instruments such as X-ray and FDR, it was discovered that the gold plating layer at the end of the pin had peeled off, which could easily cause ICI Fail.

2024/01/11

Product ICI Fail & Pin Low Life Time

Although the pin tip was not blunted, but when analyzed through related instruments such as X-ray and FDR, it was discovered that the gold plating layer at the end of the pin had peeled off, which could easily cause ICI Fail.

-

Socket SB21512 Fail Issue

2024/01/11

Socket SB21512 Fail Issue

3ea socket had SB21512 Fail during NPI engineering, and the true cause could not be found. Pin-Jet helped discover that the customer’s socket had wetting; however, after cleaned, reinstalled and tested, the abnormality still occurred. We cross-checked with another Corr IC and the manual test passed. It was confirmed that the read value of this Corr IC that had this abnormality easily was higher compared to the Corr IC that passed.

2024/01/11

Socket SB21512 Fail Issue

3ea socket had SB21512 Fail during NPI engineering, and the true cause could not be found. Pin-Jet helped discover that the customer’s socket had wetting; however, after cleaned, reinstalled and tested, the abnormality still occurred. We cross-checked with another Corr IC and the manual test passed. It was confirmed that the read value of this Corr IC that had this abnormality easily was higher compared to the Corr IC that passed.

-

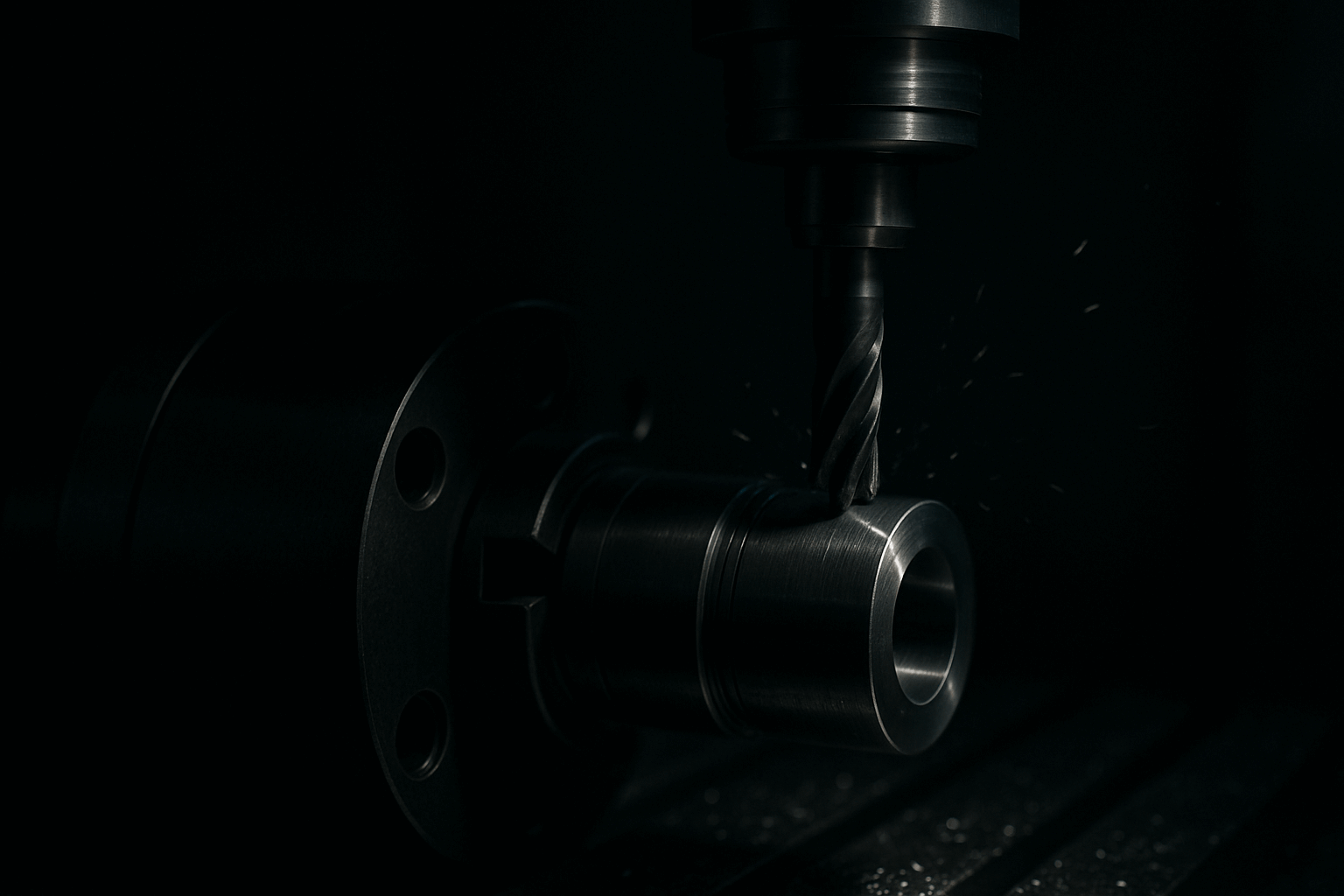

SLT Test Low Yield

2024/01/11

SLT Test Low Yield

The customer gave the feedback that the Pin Life time was approximately 70K; after confirmation by Pin-Jet, it was discovered that when the same PCB & socket was reassembled multiple times, the test results of each manual test were different. After investigation, it was found that the PCB pad was punctured and necessary to be replaced.

2024/01/11

SLT Test Low Yield

The customer gave the feedback that the Pin Life time was approximately 70K; after confirmation by Pin-Jet, it was discovered that when the same PCB & socket was reassembled multiple times, the test results of each manual test were different. After investigation, it was found that the PCB pad was punctured and necessary to be replaced.

-

SB5XXX LDO Item Test Fail

2024/01/11

SB5XXX LDO Item Test Fail

The customer gave the feedback that the LDO item failed easily; after manual testing, it was confirmed that it passed stably with no LDO item fails. After Pin-Jet aligned with the customer, problems with the LDO item occurred easily when contact mool was used; after confirming, it was found that the reason was because the customer had insufficient clamp force, which caused poor contact.

2024/01/11

SB5XXX LDO Item Test Fail

The customer gave the feedback that the LDO item failed easily; after manual testing, it was confirmed that it passed stably with no LDO item fails. After Pin-Jet aligned with the customer, problems with the LDO item occurred easily when contact mool was used; after confirming, it was found that the reason was because the customer had insufficient clamp force, which caused poor contact.

-

Clean Pad Drop Error Abnormality

2024/01/11

Clean Pad Drop Error Abnormality

The customer gave the feedback that the clean pad would not fall after the vacuum in the NEST was broken; after confirmation by Pin-Jet, it was found that there was inverted round corners inside the NEST, but the clean pad had a right-angle exterior, which caused interference.

2024/01/11

Clean Pad Drop Error Abnormality

The customer gave the feedback that the clean pad would not fall after the vacuum in the NEST was broken; after confirmation by Pin-Jet, it was found that there was inverted round corners inside the NEST, but the clean pad had a right-angle exterior, which caused interference.

Contact Us Now

Complete online forms and Pin-Jet will have representatives to help you with professional services